❮

❯

4-AXIS CNC MACHINING CENTER, IDEAL FOR MACHINING STEEL, ALUMINUM AND ALLOYS

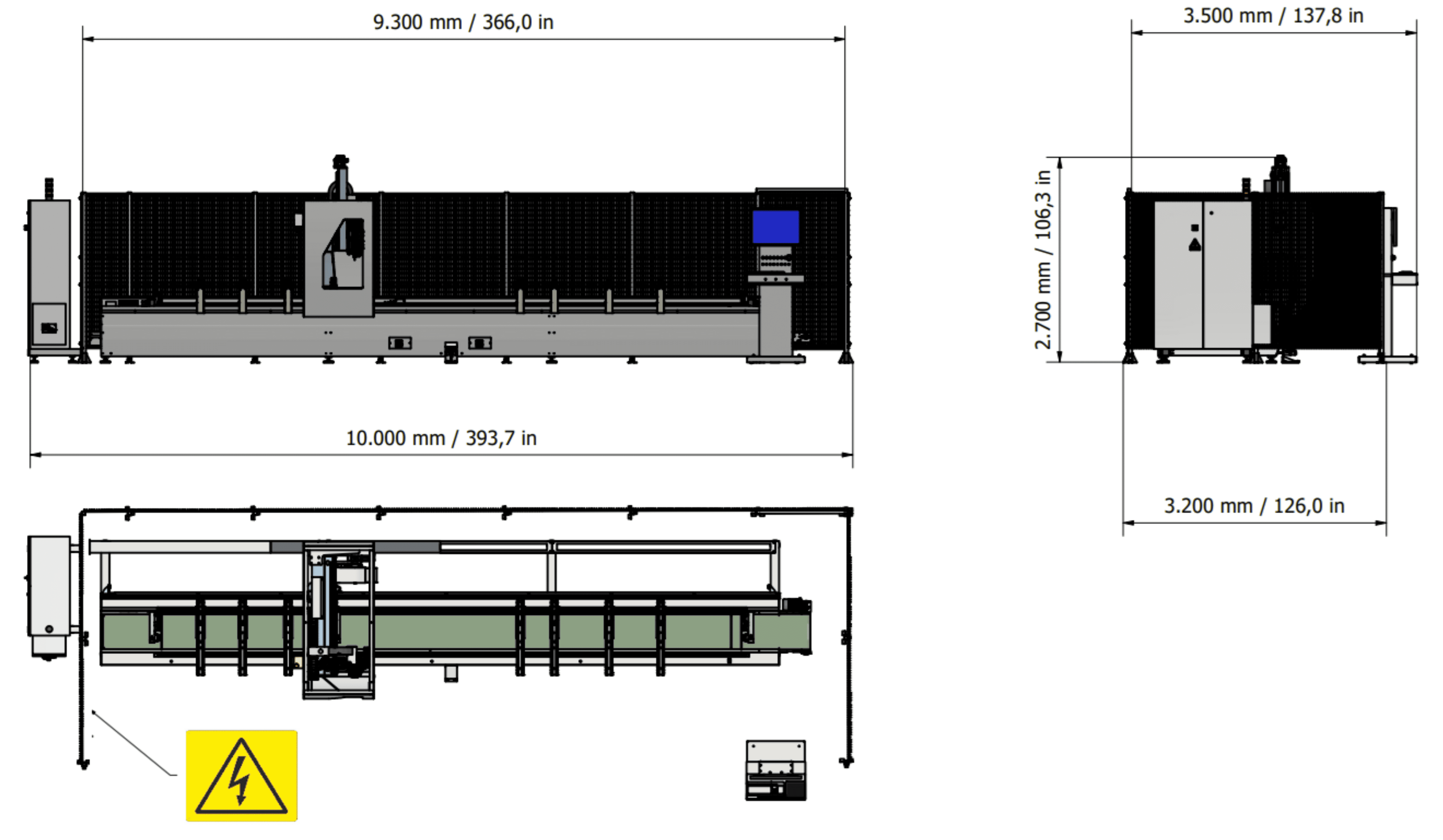

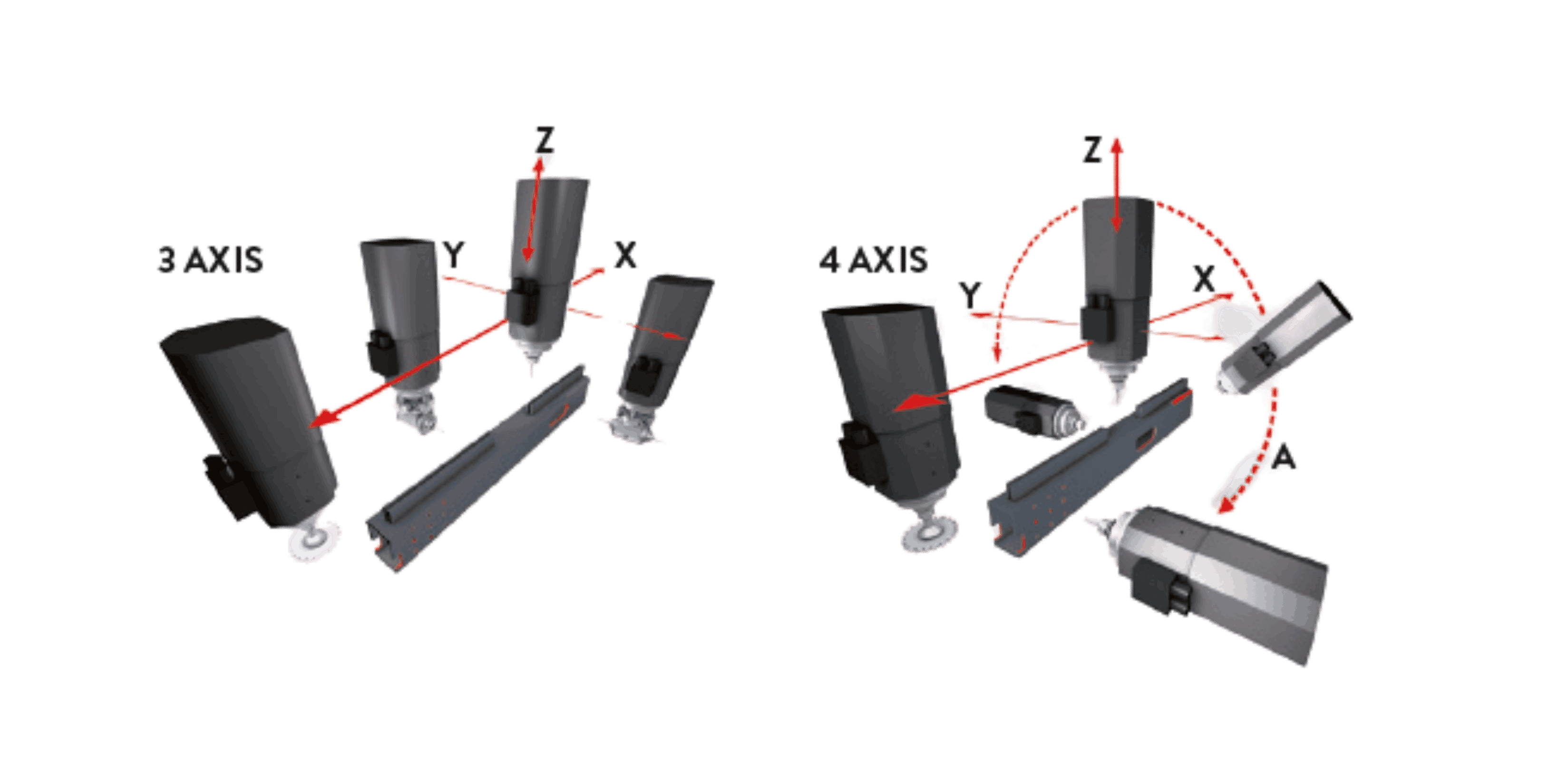

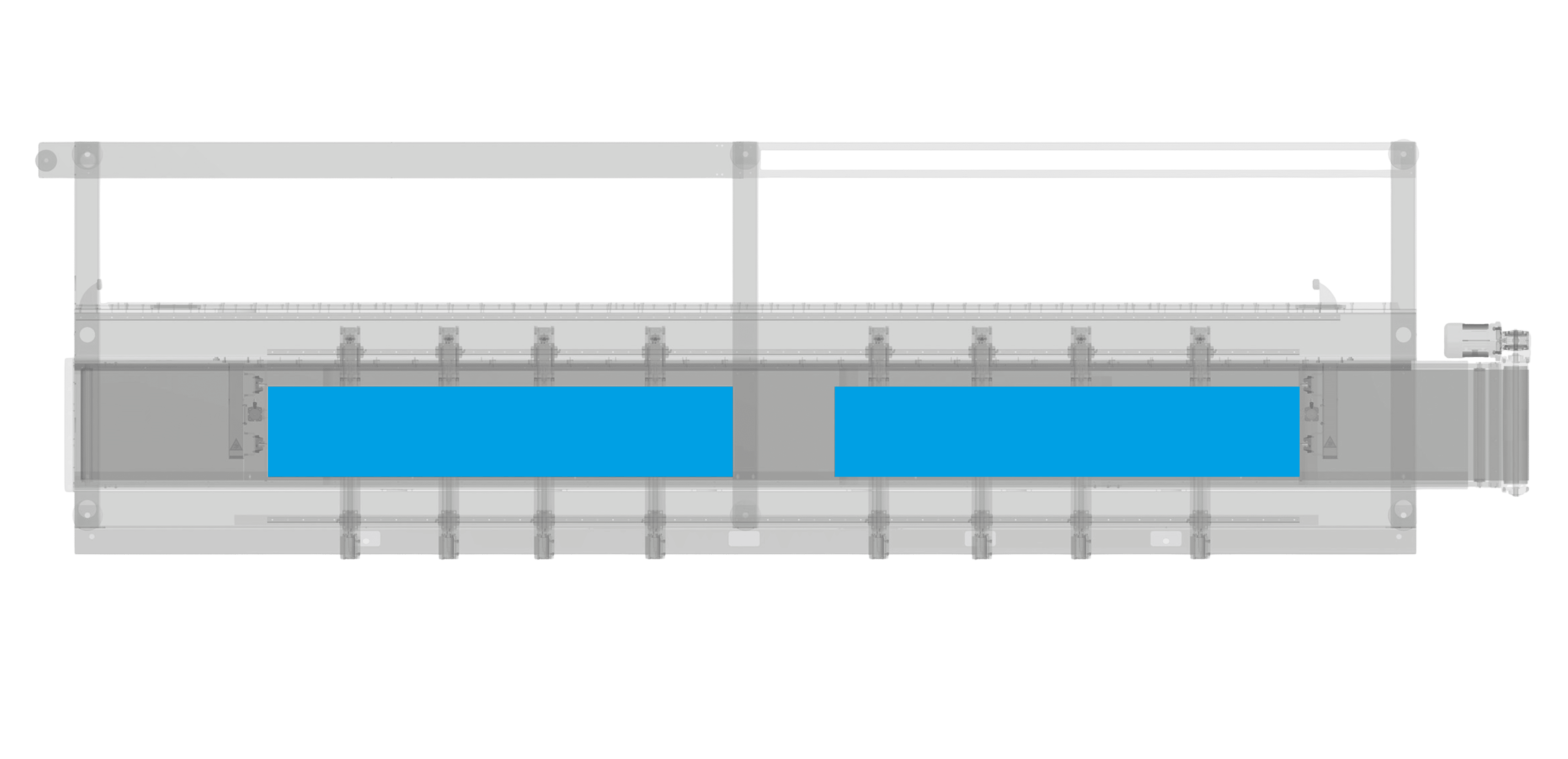

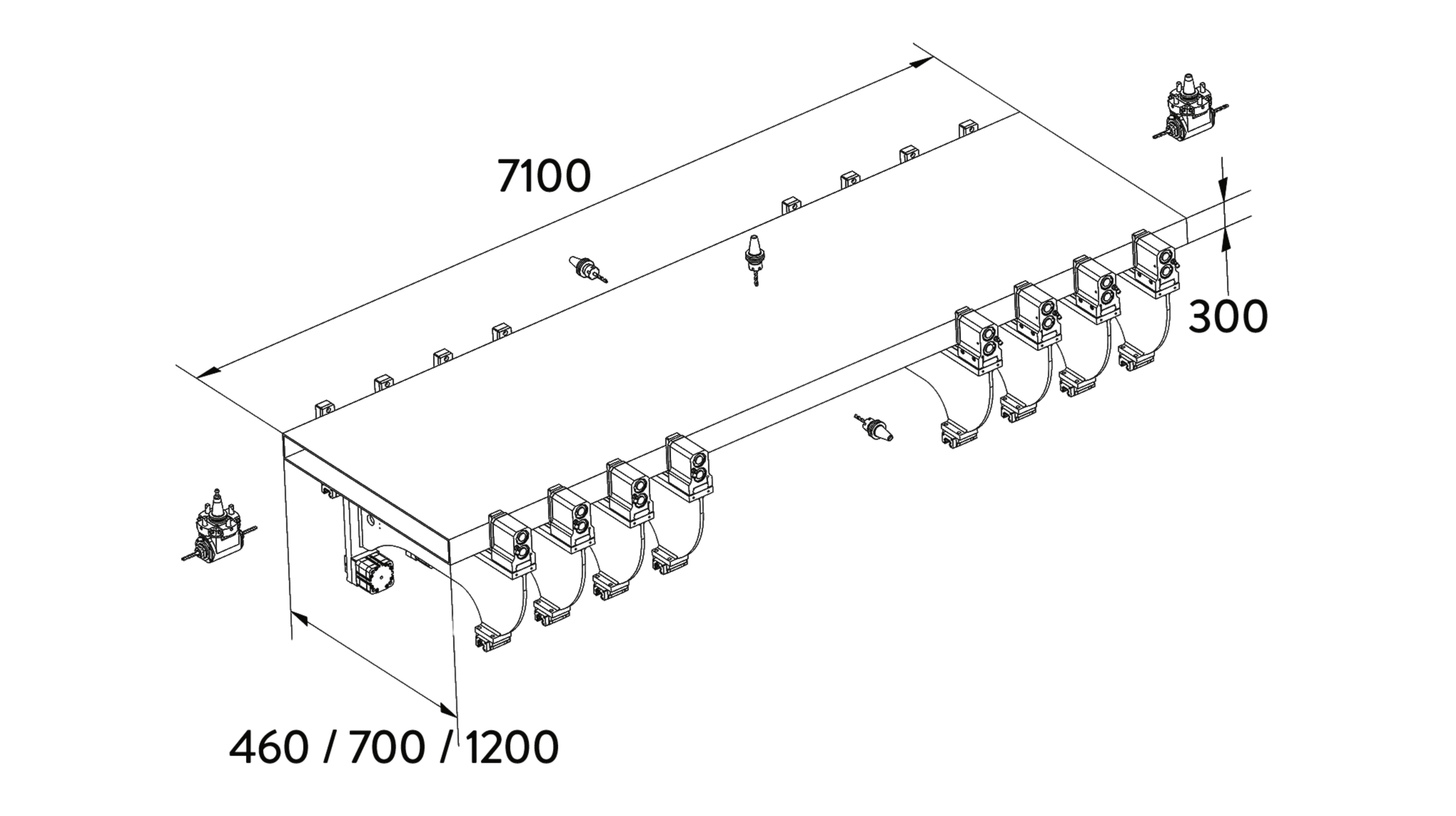

Perfect for the aeronautics, railway, automotive and construction industries. The MC400 is a 4-axis CNC machine designed to guarantee maximum versatility and precision in the machining of steel, aluminum and light alloys. Thanks to its large operating area of 700 x 350 mm, it offers high performance and adaptibility to different production needs. Available in the standard versions of 7 and 9 meters, it can be extended up to 11 and 14 meters, ensuring greater machining capacity. In all configurations, it is possible too choose the version with or without cabin, with single or double work area, to optimize production times.

Innovation and Versatility

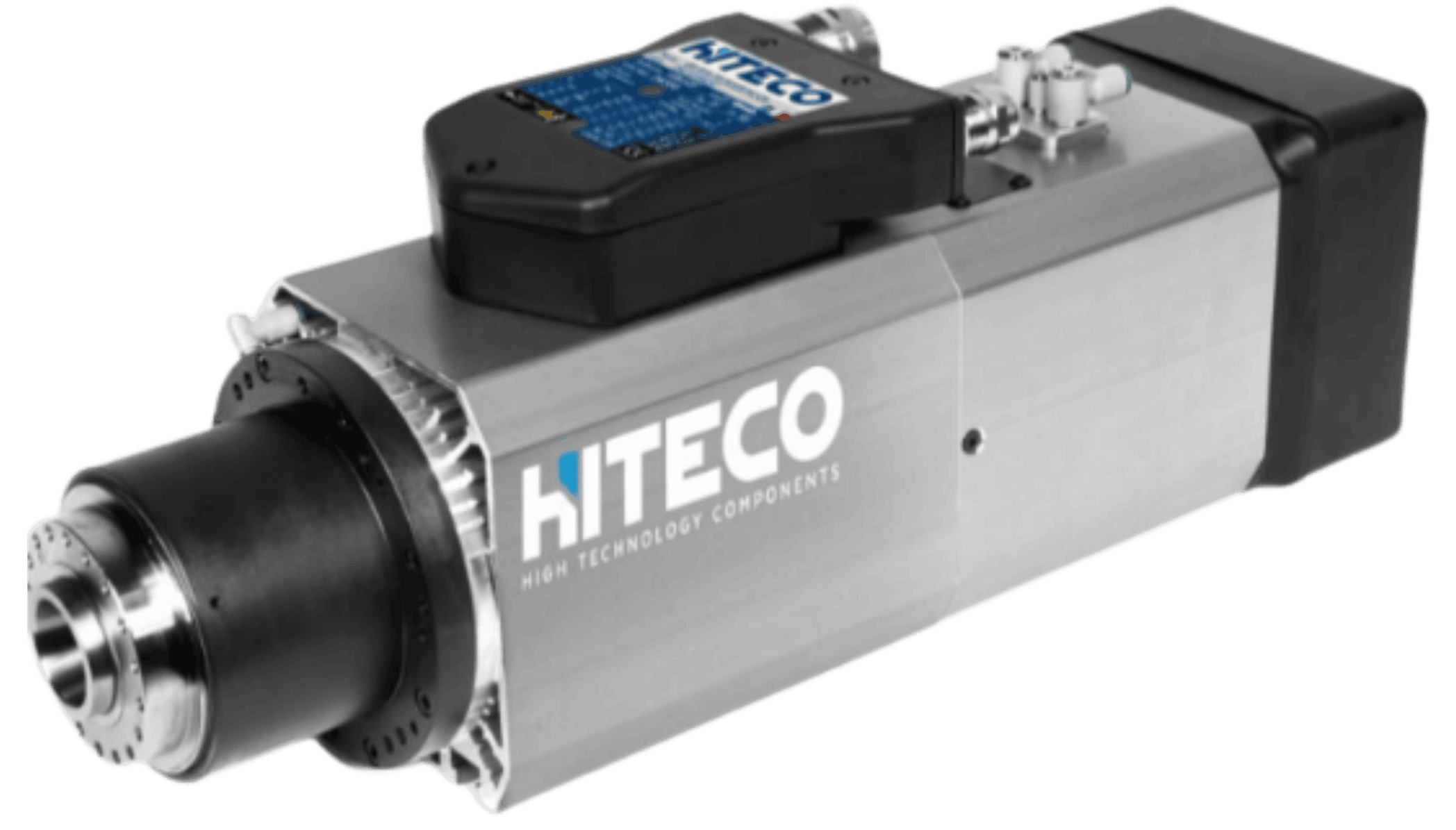

- High-performance electrospindle with 8.5 kW power in S1 (optional up to 10 kW), with HSK-F63 cone attachment, ideal for heavy-duty machining.

- Continuous rotation of the A axis from 0° to 180°, allowing machining in any position.

- 10-position rotating tool magazine, housed on the carriage, compatible with standard cutters and disc cutters expandable up to 30 positions.

- Automatic vices configurable with 8 or 12 units, positionable along the X axis in automatic mode via mobile carriage or independent with dedicated axis.

- Advanced refrigeration system, with emulsified oil via pumps on the mobile carriage,or with water-oil unit with recycling pump, for optimal temperature management.

Special Applications

The MC400 is designed to process complex materials, including fiberglass, steel and light alloys, adapting to the needs of advanced industrial sectors. Thanks to its robust structure, it is able to handle heavy machining on steel, machining for the aeronautical sector and materials subject to temperature variations. Also available in larger sizes, for the processing of sandwich panels and PVC panels, with 1,100 mm clamping and rollers to support the profiles.

Strengths

- Length from 4 to 14 meters, with single or double loading area for maximum efficiency.

- Maximum loading section 1,200 x 300 mm, ideal for advanced industrial processes.

- Enhanced 500 mm blade, which can be equipped with a 3 kW motor, for precision cuts.

- Perfect for processing sectional panels, sandwich panels and PVC, ensuring maximum adaptability to production needs.

|

Model |

7.0 |

Dimensions |

6,300 x 3,100 x 2,400 mm |

|

Transport dimensions |

L 11.500 W 2.300 H 2.200 mm |

|

Layout dimension standard |

L 9.600 W 3.600 H 2.550 mm |

|

Weight |

4.800 Kg |

|

Nominal power |

24 kW |

|

Consume power |

15 kW |

|

Required protection |

32 A (termic: 32 A, differential 0.1 A, magnetic interruption 6.000 A) |

|

Voltage |

400 V, 3-phase + Neutral + Ground |

|

Minimum air pressure |

0.65 Psi |

|

Air consume |

240 NL/M |

|

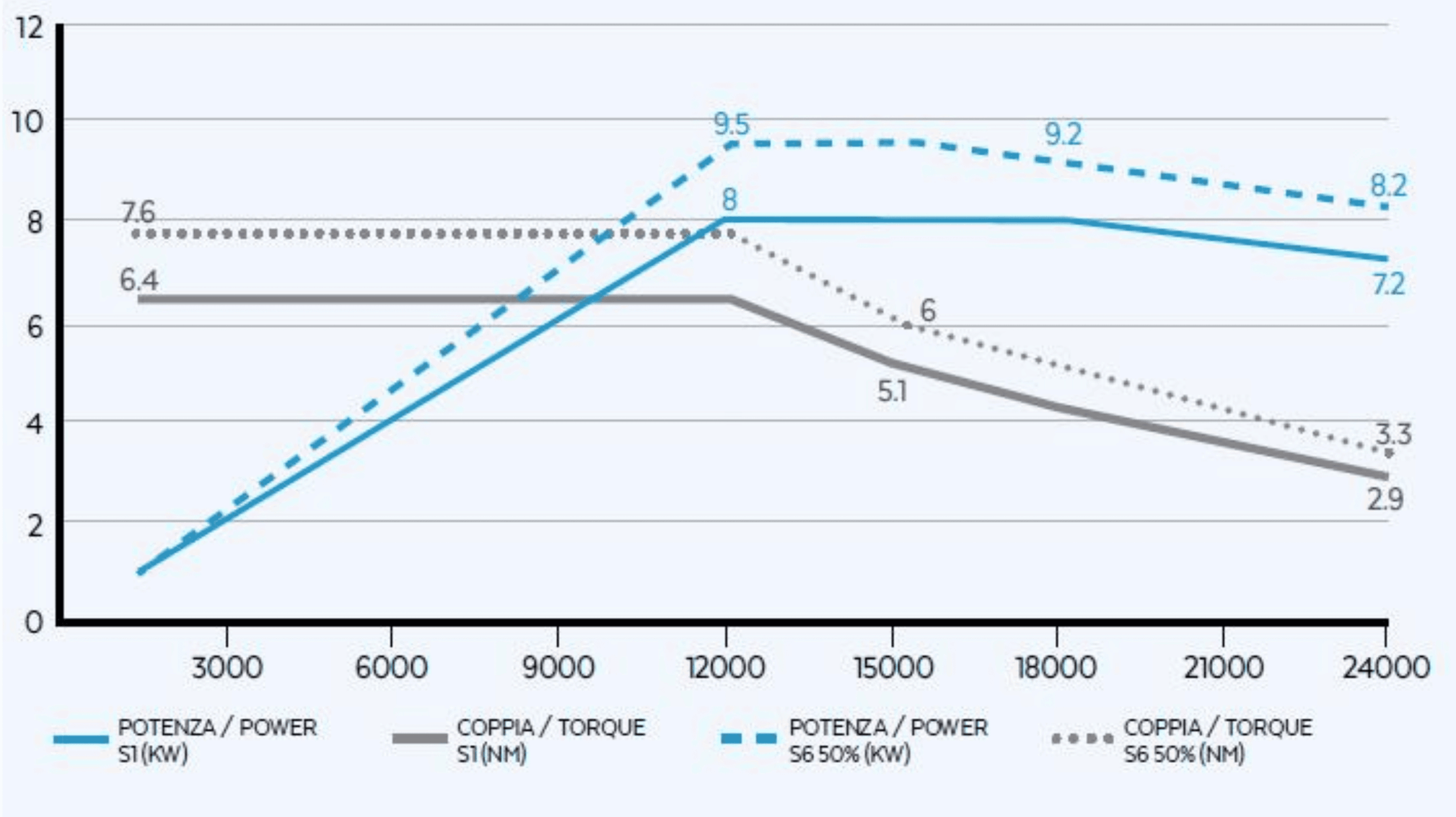

Nominal power of Electrospindle |

8/9.5 kW |

|

Nominal torque |

6.4/7.6 Nm at 12.000 RPM |

|

Tool holder type |

HSK F63 |

|

Max speed |

24.000 rpm |

|

Tool cooling |

CNC regulated micro pump |

|

Spindle cooling system |

Electro fan |

|

Oil tank capacity |

1 Lt |

|

X-axis travel Y-axis travel Z-axis travel A-axis rotation C-axis |

7.100 mm 640 mm 340 mm - extra 440 mm option 180° Not applicable to this model |

|

Max speed X Max speed Y Max speed Z Max speed A Max speed C |

90 m/min 60 m/min 30 m/min 3.600°/min Not applicable to this model |

|

Tool storage spot |

10 |

|

Tool storage motor |

Brushless |

|

Reference stops |

2 (CNC managed, pneumatic movement) |

|

Clamps Clamp displacement Clamp closing force |

8 standard (up to 16 on request), 4 per zone Automatic via carriage (motorized on request) 130 kg |

|

Lubrication |

Manual (central greasing points for guides and screws) |

|

Humidity limit |

80% |

|

Accuracy |

0.1 mm/m |

|

Monitor |

27" |

|

Operating system |

Win11 |

|

Connections |

USB (1 port), LAN, Wi-Fi |