❮

❯

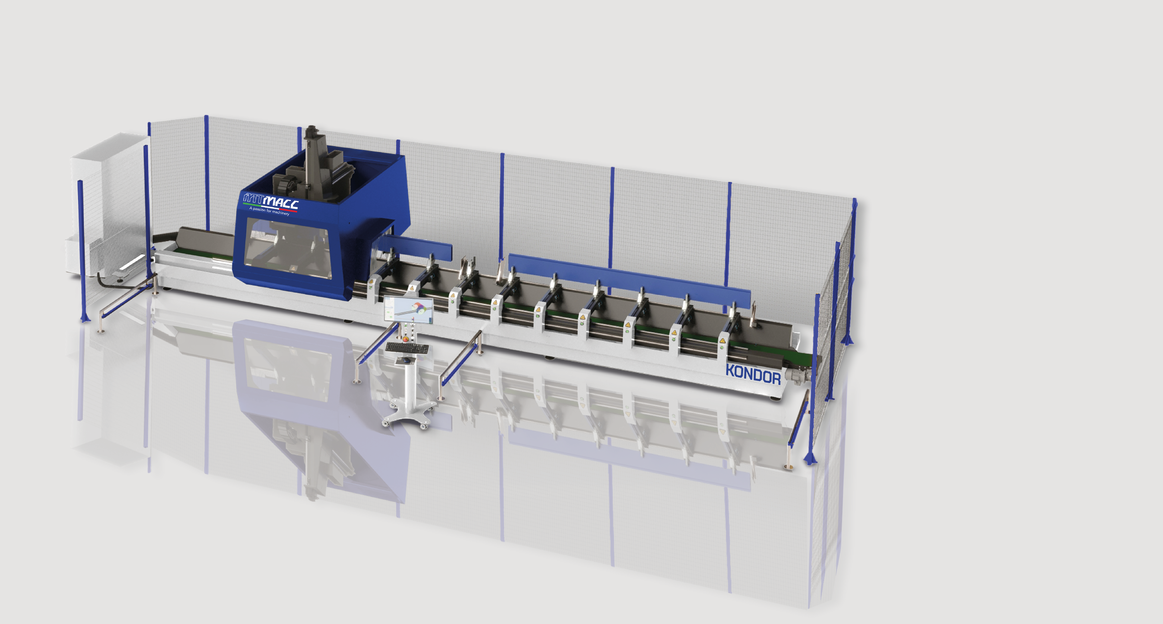

Especialmente indicado para la industria ligera y adecuado para el procesamiento de acero, aluminio y aleaciones. Dispone de una amplia gama de electromandrinos de 8, 12 y 16 kW, mordazas de alto rendimiento con movimiento automático por el carro o reordenamiento rápido de la superficie de carga. Disponibles en versiones de 4, 7, 9, 11 y 13 metros también con doble sujeción y con soportes para cabezales angulares indicados para procesos específicos. Su cambiador de herramientas básico incluye 15 posiciones, pero bajo pedido se puede ampliar hasta 30. La sección trabajable de 300 x 640 mm permite un amplio funcionamiento para satisfacer todas las necesidades. Entre sus características destacadas, el MC 500 incluye: una hoja de 400 mm y una hoja de herramienta que se puede combinar con el conjunto de hoja accesoria de 500 mm. MC 500 es perfecto para fachadas, perfiles de construcción, industria del automóvil, luminotecnia, sector ferroviario y todas las industrias ligeras en general.

|

MODEL |

7.0 |

|

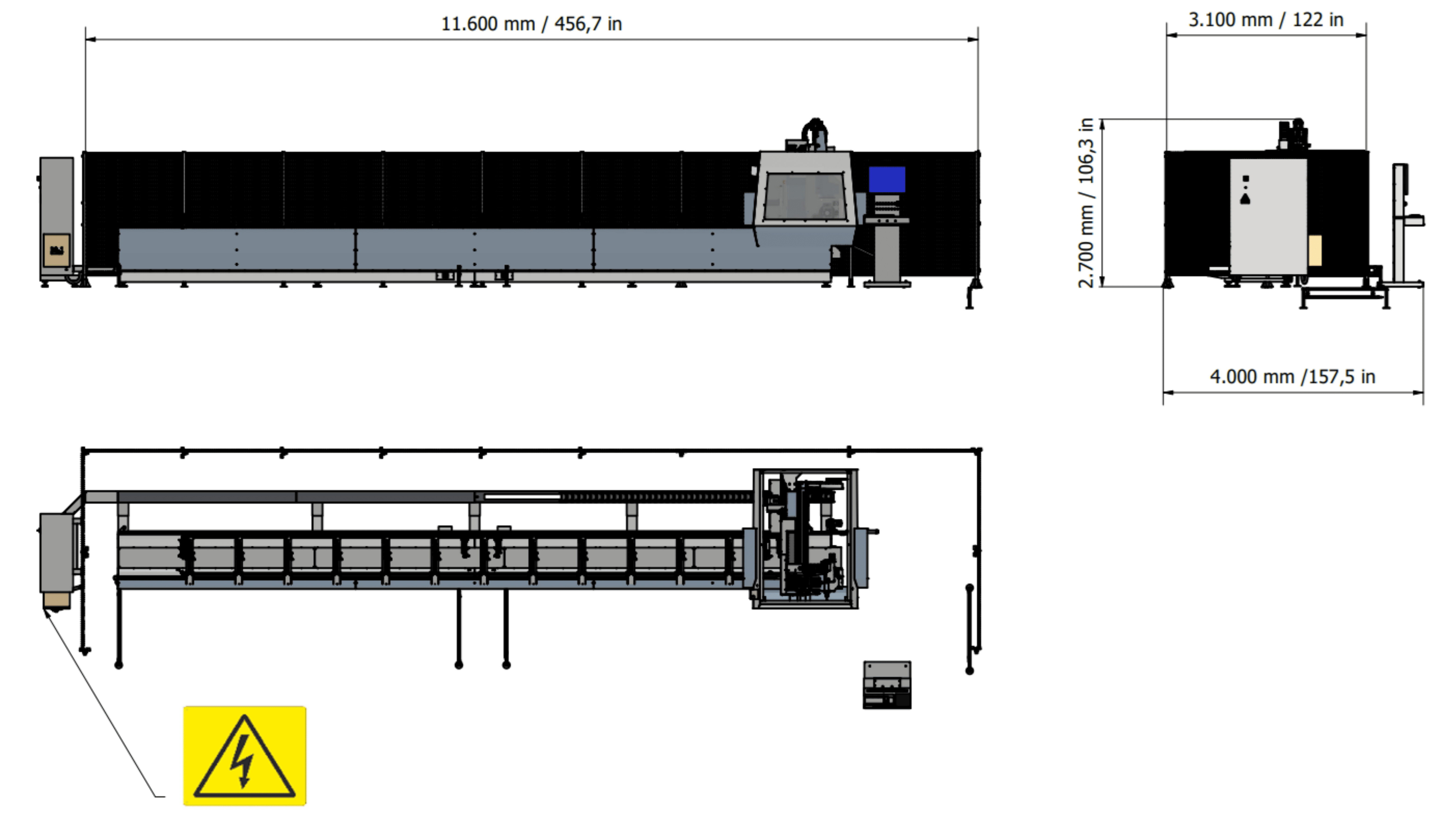

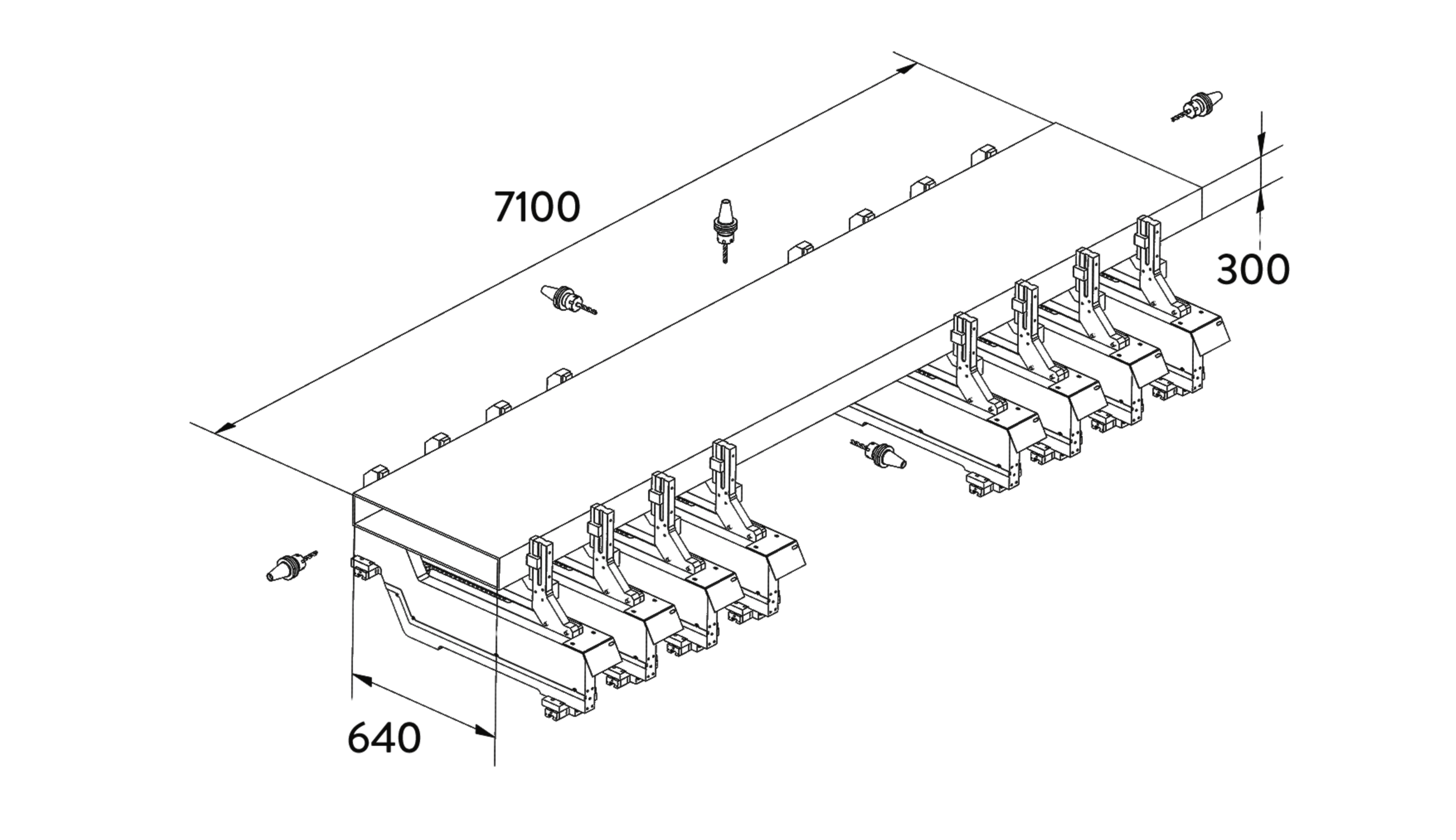

Dimensions |

7.100 x 460 x 300 mm |

|

Transport dimension |

L 8.900 W 2.400 H 2.500 mm |

|

Layout dimension standard |

L 9.800 W 3.530 H 3.450 mm |

|

Weight |

7.200 Kg |

|

Nominal power |

40 kW |

|

Consume power |

32 kW |

|

Required protection |

63 A differential thermal, 0.1 A, adjustable, 6.000 A magnetic) |

|

Voltage |

400 V, 3-phase + Neutral ±5% |

|

Frequency |

50/60 Hz |

|

Minimum air pressure |

7 bar |

|

Air consume |

230 NL/M |

|

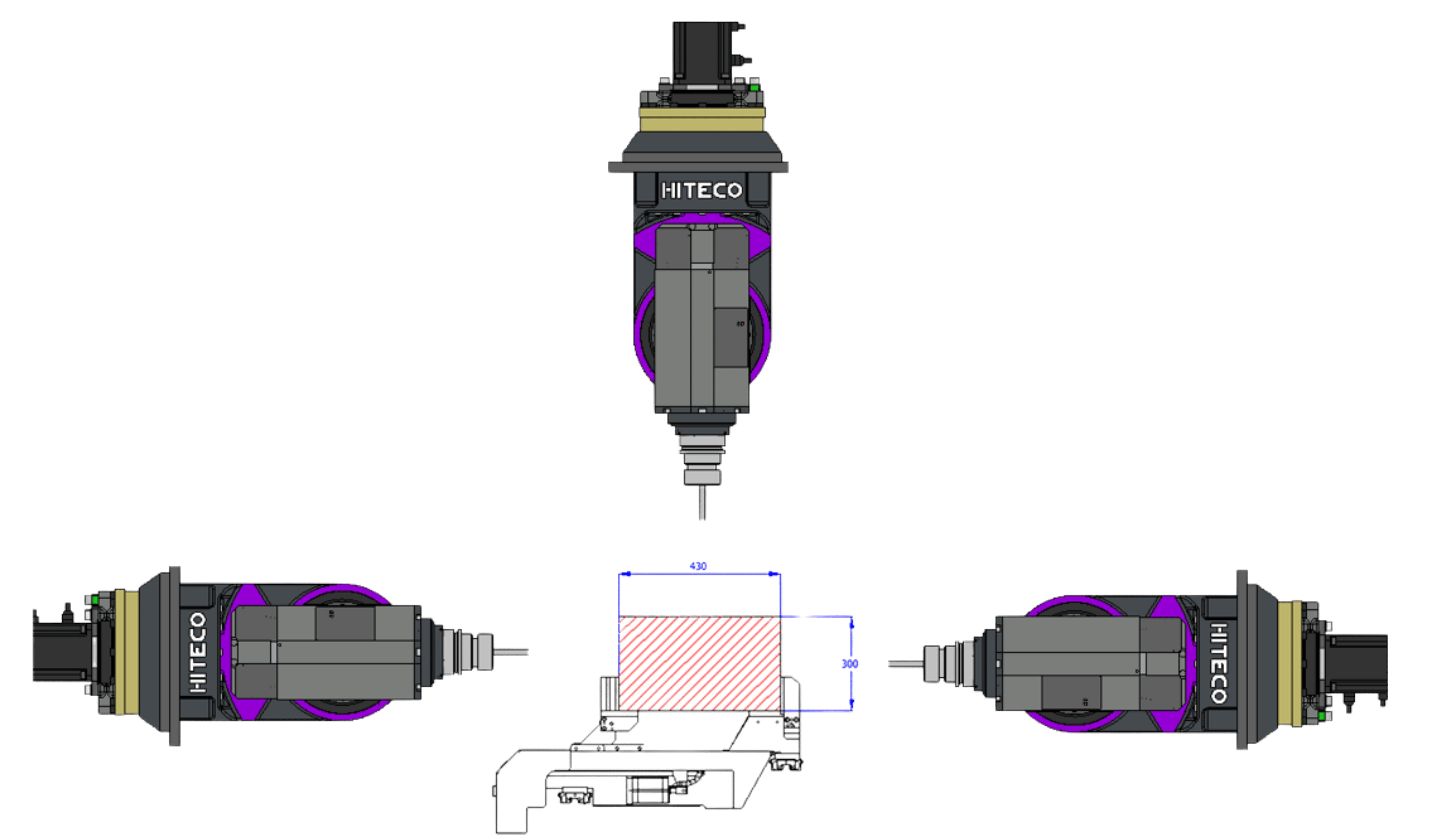

Nominal power of Electrospindle |

12 kW |

|

Nominal torque |

12.8 Nm at 12.000 RPM |

|

Tool holder type |

HSK F63 |

|

Tool cooling |

Micro pulses by means of CNC-controlled pump |

|

Spindle cooling system |

Liquid, with cooling unit |

|

Oil tank capacity |

2.2 Lt |

|

Number of nozzles |

2 |

|

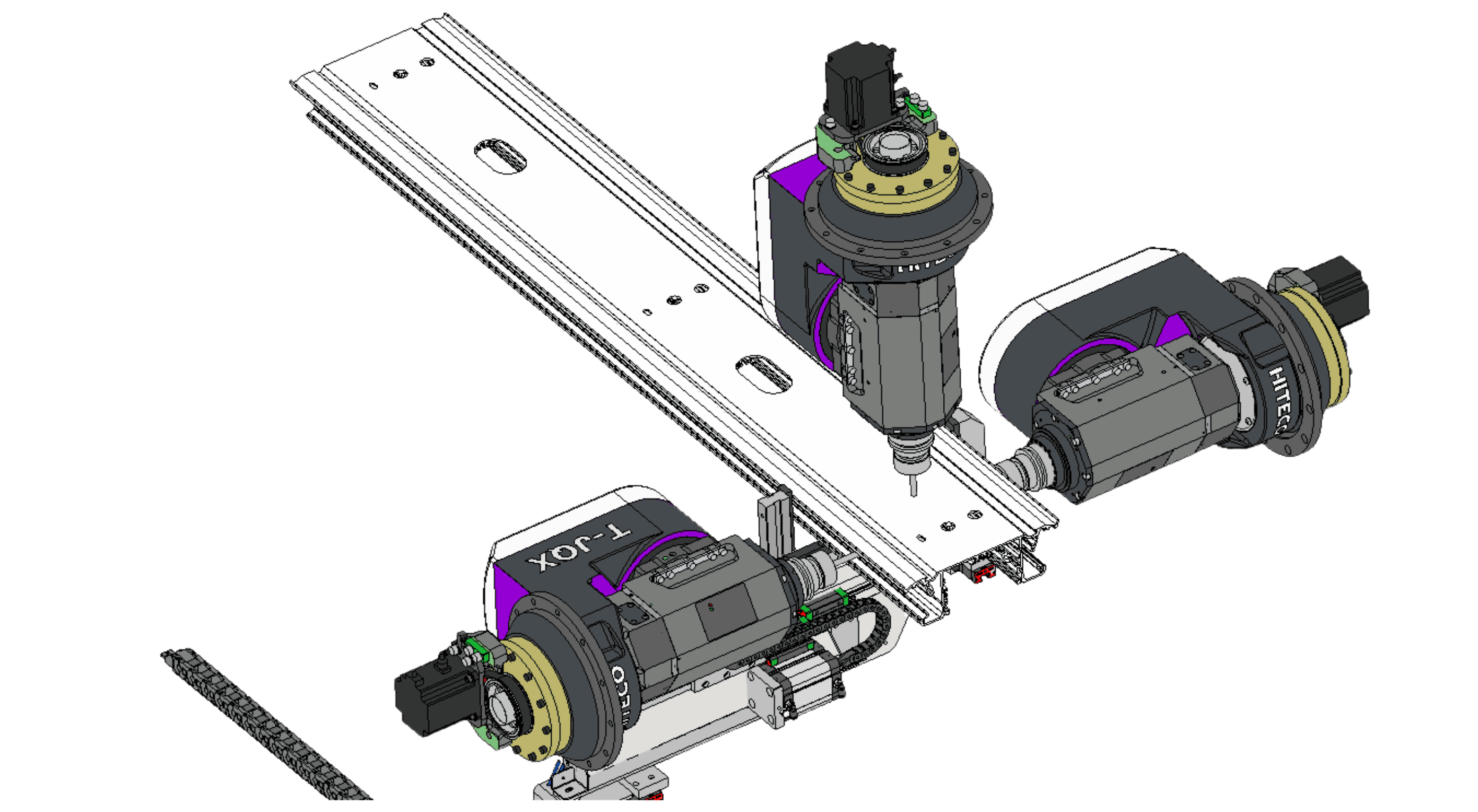

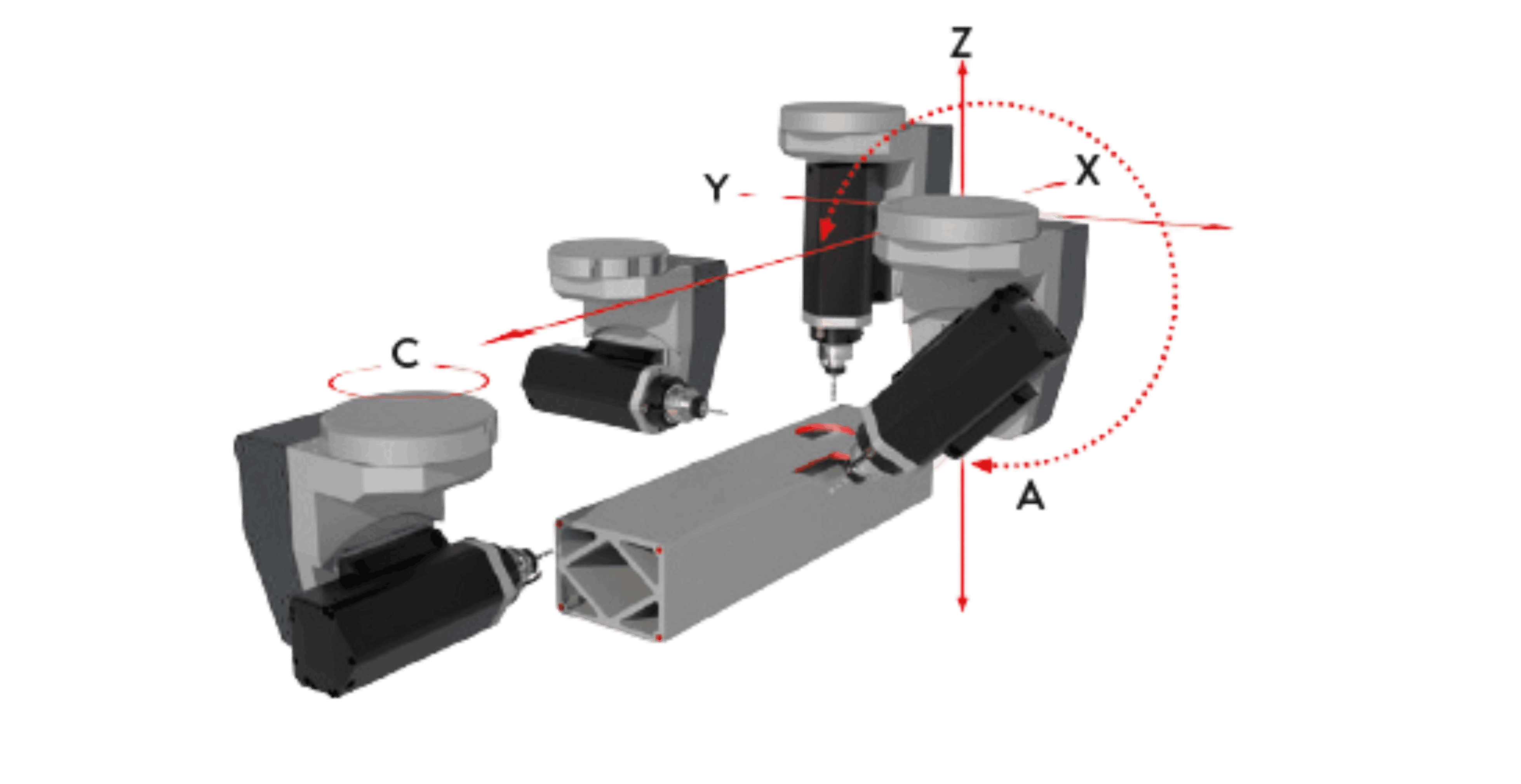

X-axis travel Y-axis travel Z-axis travel A-axis rotation C-axis |

7.100 mm 460 mm 4 axes 300 mm 180° 360° |

|

Max speed X Max speed Y Max speed Z Max speed A Max speed C |

90 m/min 60 m/min 30 m/min 3.600°/min 1.800°/min |

|

Tool storage stop |

15 (optional 15-20-32) |

|

tool storage motor |

Brushless |

|

Reference stops |

2 |

|

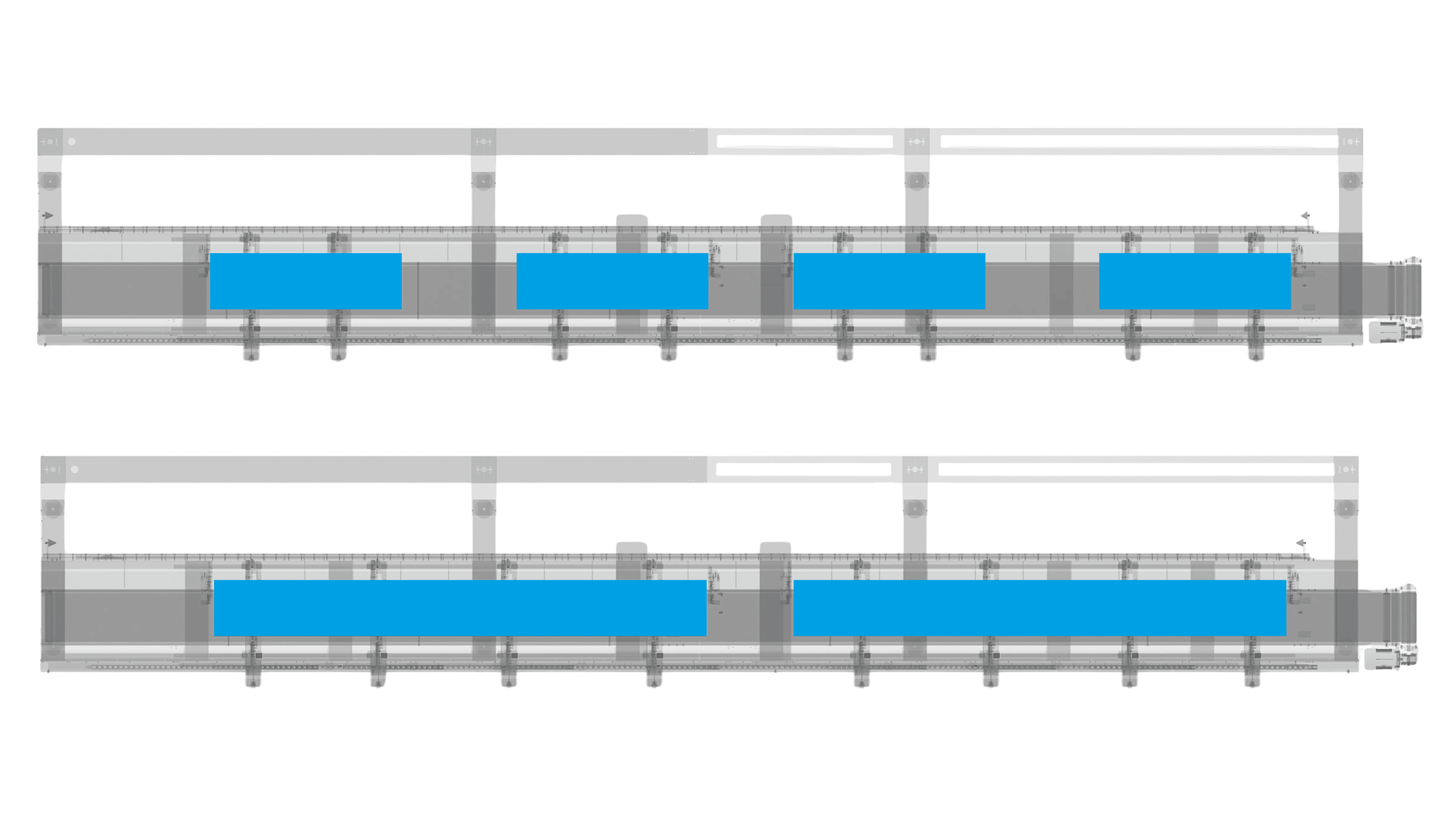

Clamps Clamp displacement Clamp closing force |

8 standard (up to 16 on request), 4 per zone Automatic via trolley (motorized on request) 120 kg |

|

Lubrication - trolley bearings Lubrication - screw carriage Lubrication - clamps |

Automatic - CNC managed Automatic - CNC managed Automatic - CNC managed |

|

Humidity limit |

75% |

|

Accuracy |

0.1 mm/m |

|

Monitor |

27" |

|

Operating system |

Win11 |

|

Connections |

USB (1 port), LAN, Wi-Fi |

|

MODEL |

9.0 |

|

Dimensions |

9.100 x 460 x 300 mm |

|

Transport dimensions |

L 11.000 W 2.400 H 2.500 mm |

|

Layout dimension standard |

L 11.800 W 3.530 H 3.450 mm |

|

Weight |

7.200 Kg |

|

Nominal power |

40 kW |

|

Consume power |

32 kW |

|

Required protection |

63 A differential thermal, 0.1 A, adjustable, 6.000 A magnetic) |

|

Voltage |

400 V, 3-phase + Neutral ±5% |

|

Frequency |

50/60 Hz |

|

Minimum air pressure |

7 bar |

|

Air consume |

230 NL/M |

|

Nominal power of Electrospindle |

12 kW |

|

Nominal torque |

12.8 Nm at 12.000 RPM |

|

Tool holder type |

HSK F63 |

|

Tool cooling |

Micro pulses by means of CNC-controlled pump |

|

Spindle cooling system |

Liquid, with cooling unit |

|

Oil tank capacity |

2.2 Lt |

|

Number of nozzles |

2 |

|

X-axis travel Y-axis travel Z-axis travel A-axis rotation C-axis |

9.100 mm 460 mm 4 axis 300 mm 180° 360° |

|

Max speed X Max speed Y Max speed Z Max speed A Max speed C |

90 m/min 60 m/min 30 m/min 3.600°/min 1.800°/min |

|

Tool storage spot |

15 (optional 15-20-32) |

|

Tool storage motor |

Brushless |

|

Reference stops |

2 |

|

Clamps Clamp displacement Clamp closing force |

10 standard (up to 16 on request), 5 per zone Automatic via trolley (motorized on request) 120 kg |

|

Lubrification - trolley bearings Lubrification - screw carriage Lubrification - clamps |

Automatic - CNC managed Automatic - CNC managed Automatic - CNC managed |

|

Humidity limit |

75% |

|

Accuracy |

0.1 mm/m |

|

Monitor |

27" |

|

Operating system |

Win11 |

|

Connections |

USB (1 port), LAN, Wi-Fi |