❮

❯

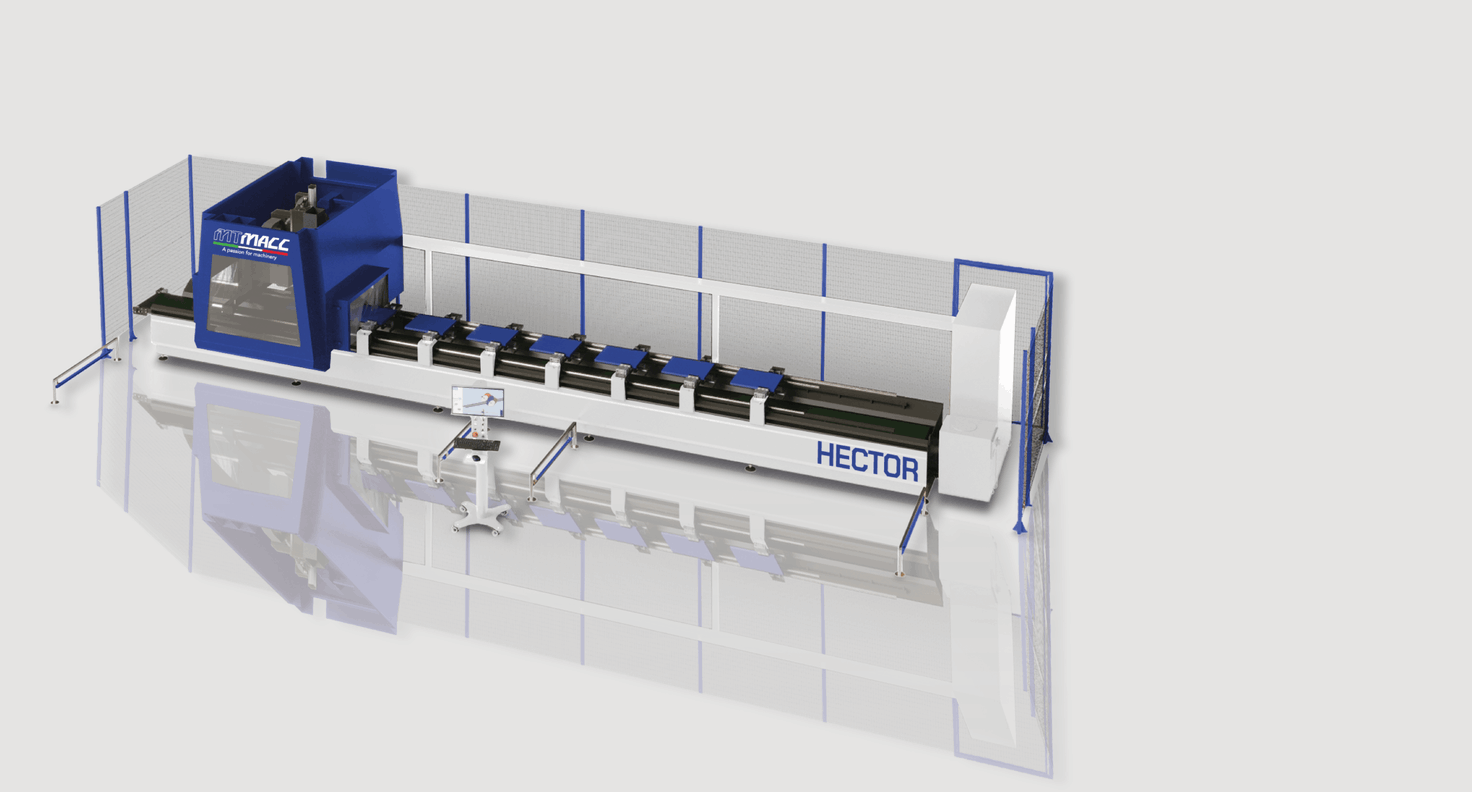

HIGH EFFICIENCY WORK CENTER, IDEAL FOR PROCESSING STEEL, ALUMINUM AND ALLOYS

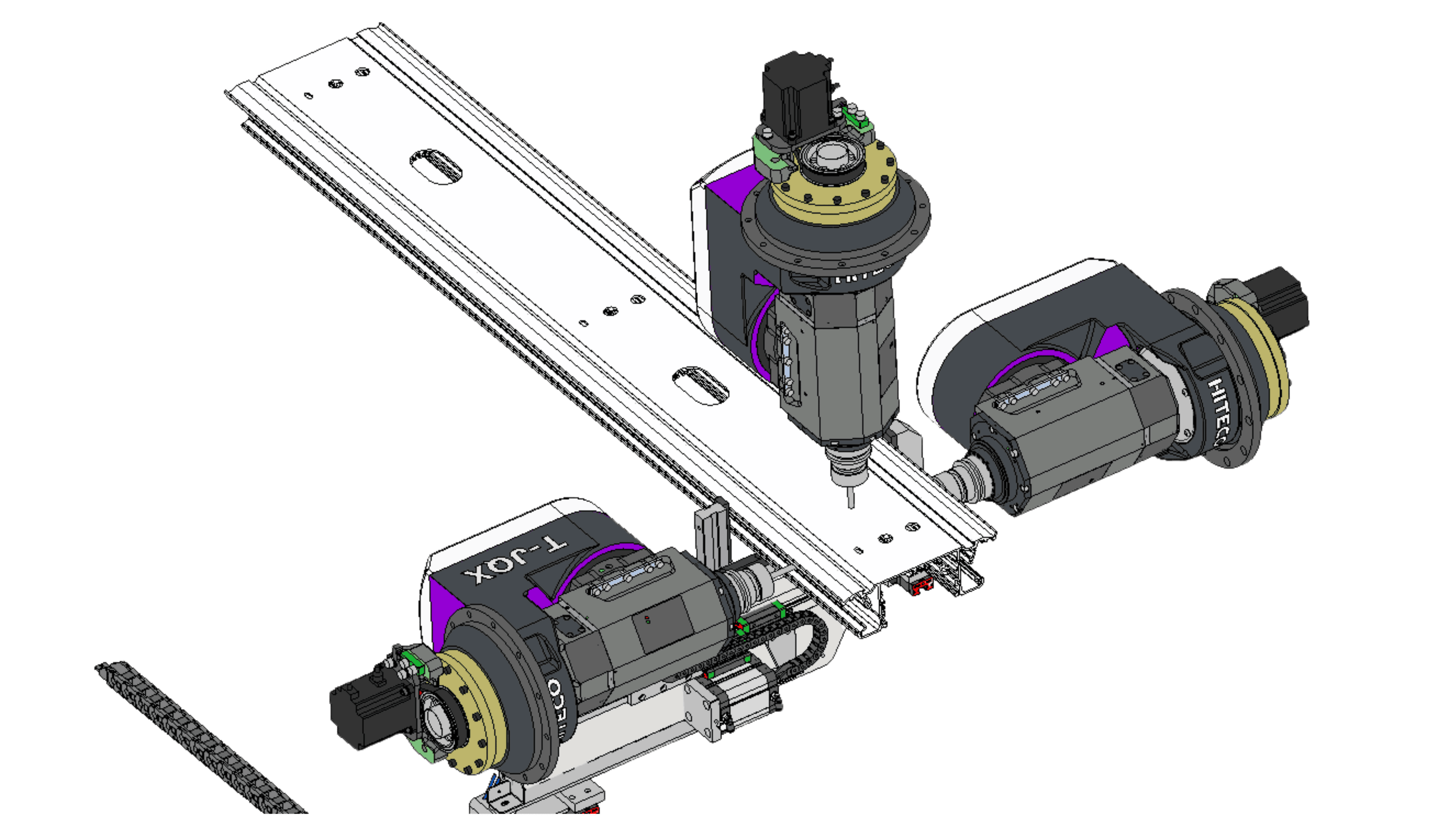

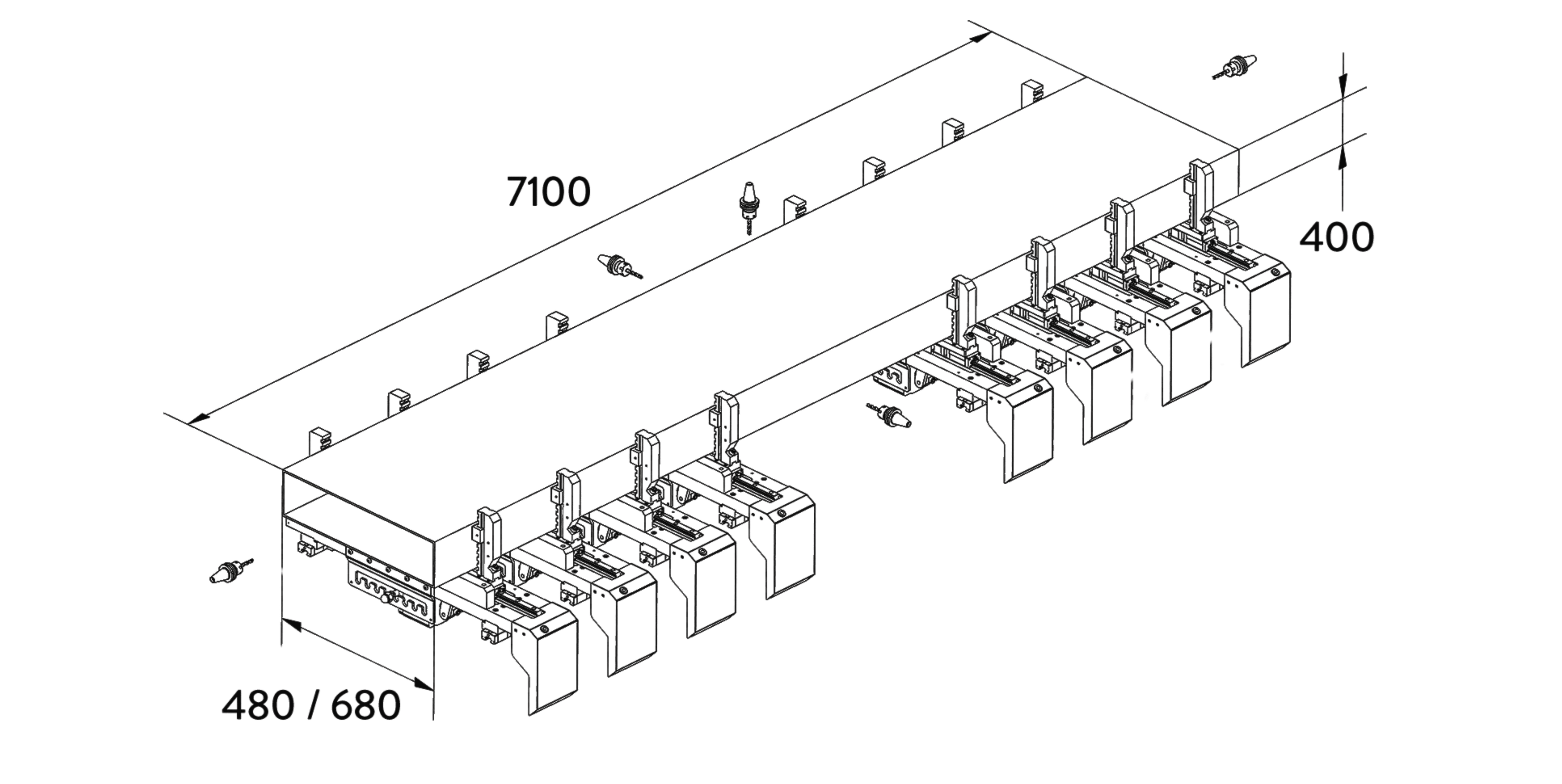

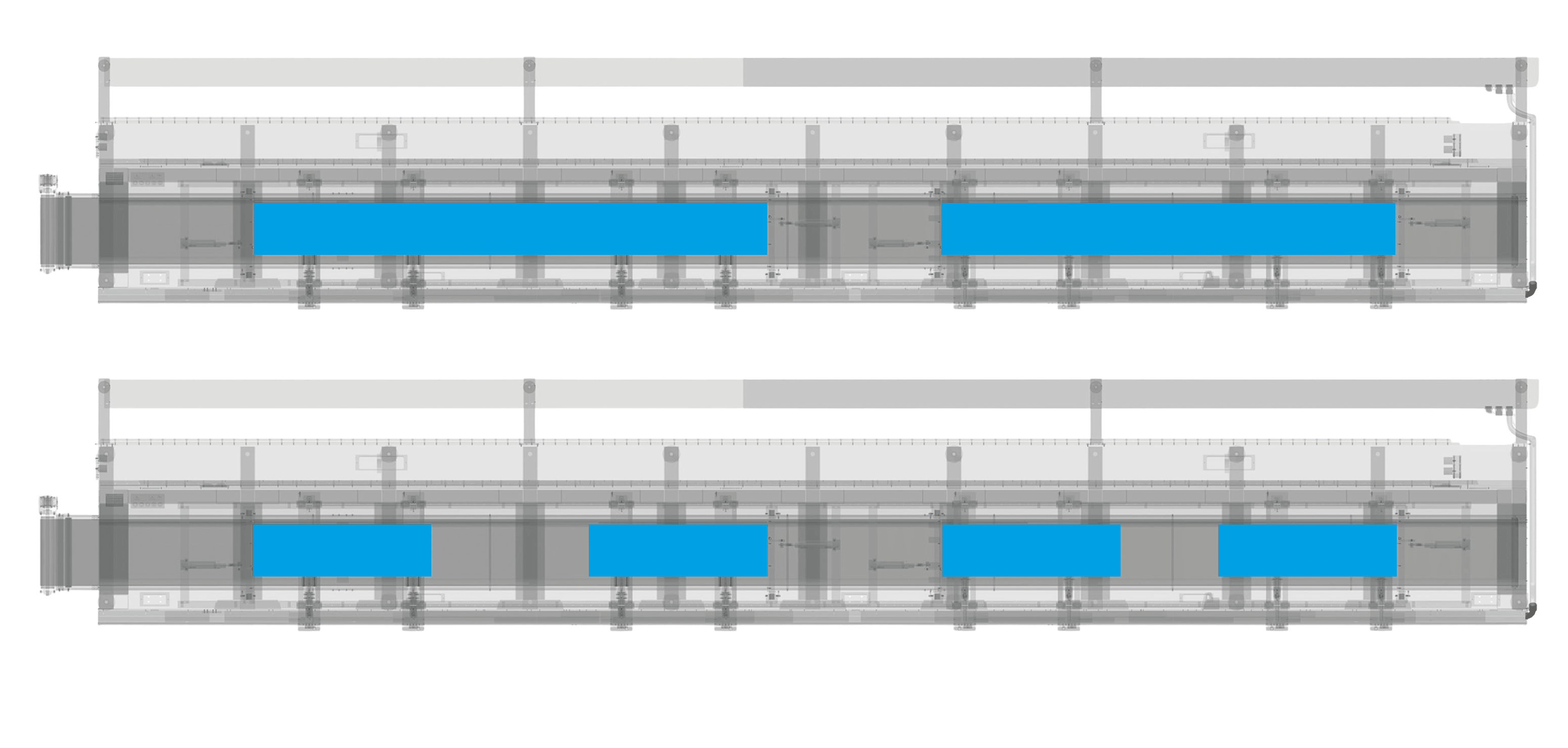

Perfect for the automotive, railway, lighting and construction industries. The MC500 is a CNC work center designed to guarantee maximum versatility and precision in the machining of steel, aluminum and light alloys, offering advanced solutions for the light industry. Thanks to its wide range of 8, 12 and 16 kW electrospindles, the MC500 ensures high performance and adaptability to different production needs. The high-performance clamps, with automatic movement via the carriage or the rearrangement of the loading surface, allow for rapid and optimized setup. Available in the 4, 7, 9, 11 and 13 meter versions, the MC500 can be configured with double clamping and supports for angular heads, ideal for specific and complex machining.

Innovation & Efficiency

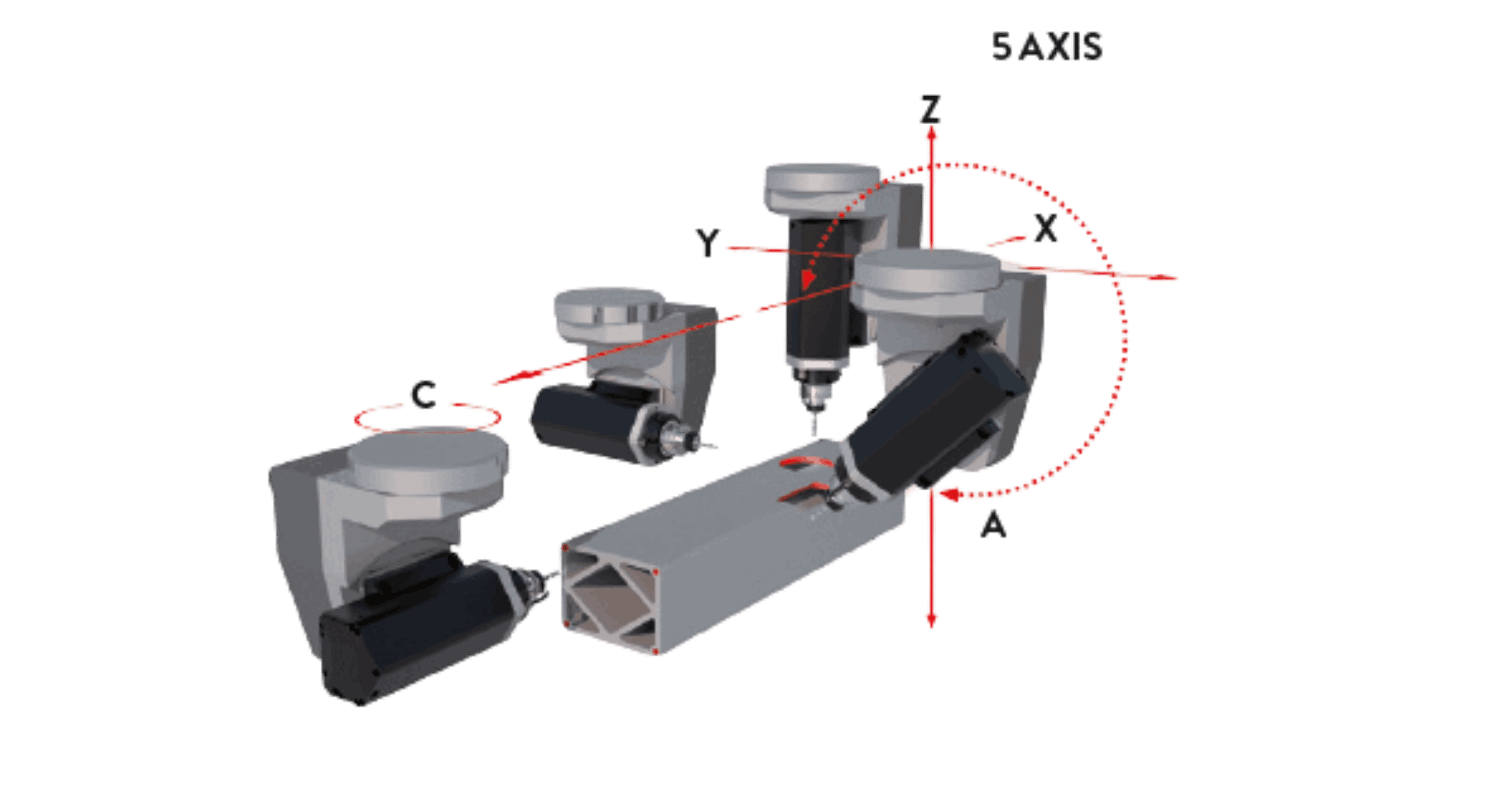

- Advanced CNC technology with 3, 4 or 5 axes, ideal for complex and high-precision machining.

- Internal tool magazine with 15 positions, extendable up to 30 on request, for greater operational flexibility.

- Workable section of 350 x 680 mm, which guarantees a wide operability to meet every production need.

- 400 mm blade and tool blade that can be combined with the 500 mm accessory blade group, for precision machining on profiles and structures.

- Perfect for facades, building profiles, the automotive industry, lighting and railway sector, adapting to the most advanced production needs.

Strengths

- High-performance electrospindles of 8, 12 and 16 kW, for machining resistant materials.

- Workable section of 350 x 680 mm, ideal for light and precision industrial machining.

- 500 mm sectioning blade, available in a fixed 90° version and a mobile version for vertical sectioning.

- 400 mm tool blade, perfect for facades, construction profiles, automotive and lighting sectors.

|

MODEL |

7.0 |

|

Dimensions |

7.100 x 640 x 400 mm |

|

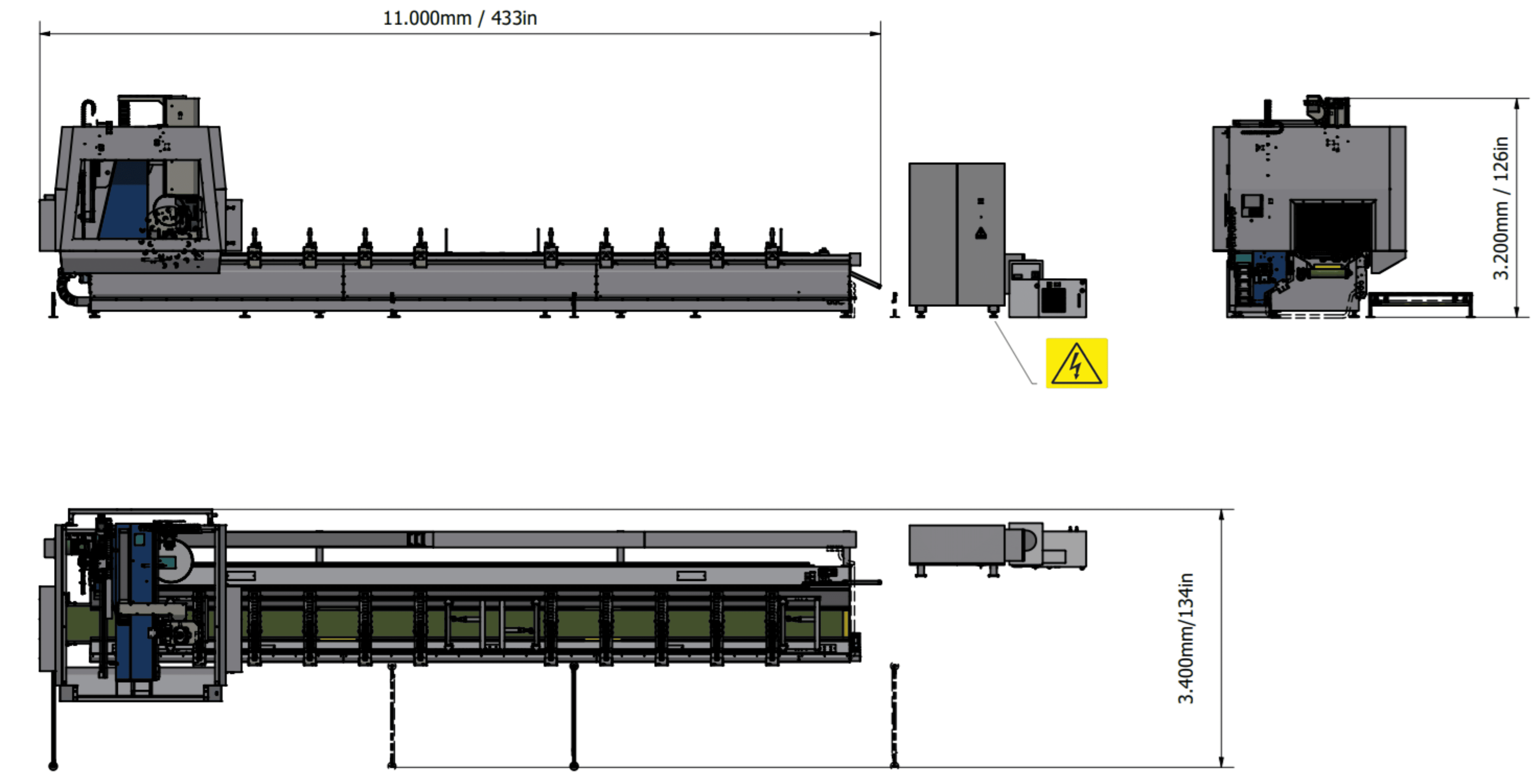

Transport dimensions |

L 11.000 W 2.400 H 2.700 mm |

|

Layout dimension standard |

L 11.800 W 3.400 H 3.200 mm |

|

Weight |

6.800 Kg |

|

Nominal power |

40 kW |

|

Consume power |

32 kW |

|

Required protection |

63 A differential thermal, 0.1 A, adjustable, 6.000 A magnetic) |

|

Voltage |

400 V, 3-phase + Neutral ±5% |

|

Frequency |

50/60 Hz |

|

Minimum air pressure |

7 bar |

|

Air consume |

230 NL/M |

|

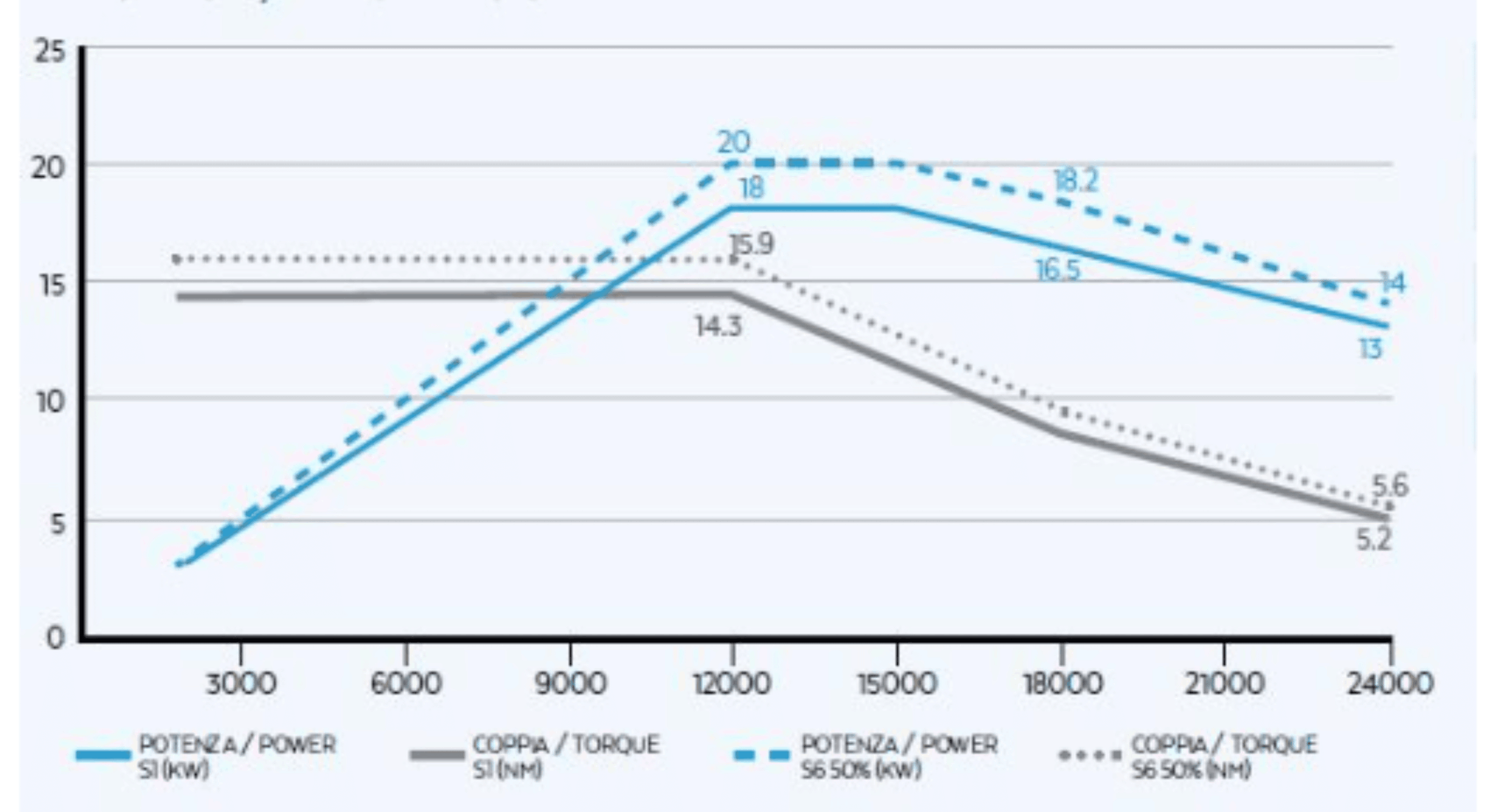

Nominal power of Electrospindle |

18 kW s1 / 20 kW s6 |

|

Nominal torque |

14.3/15.9 Nm at 12.000 RPM |

|

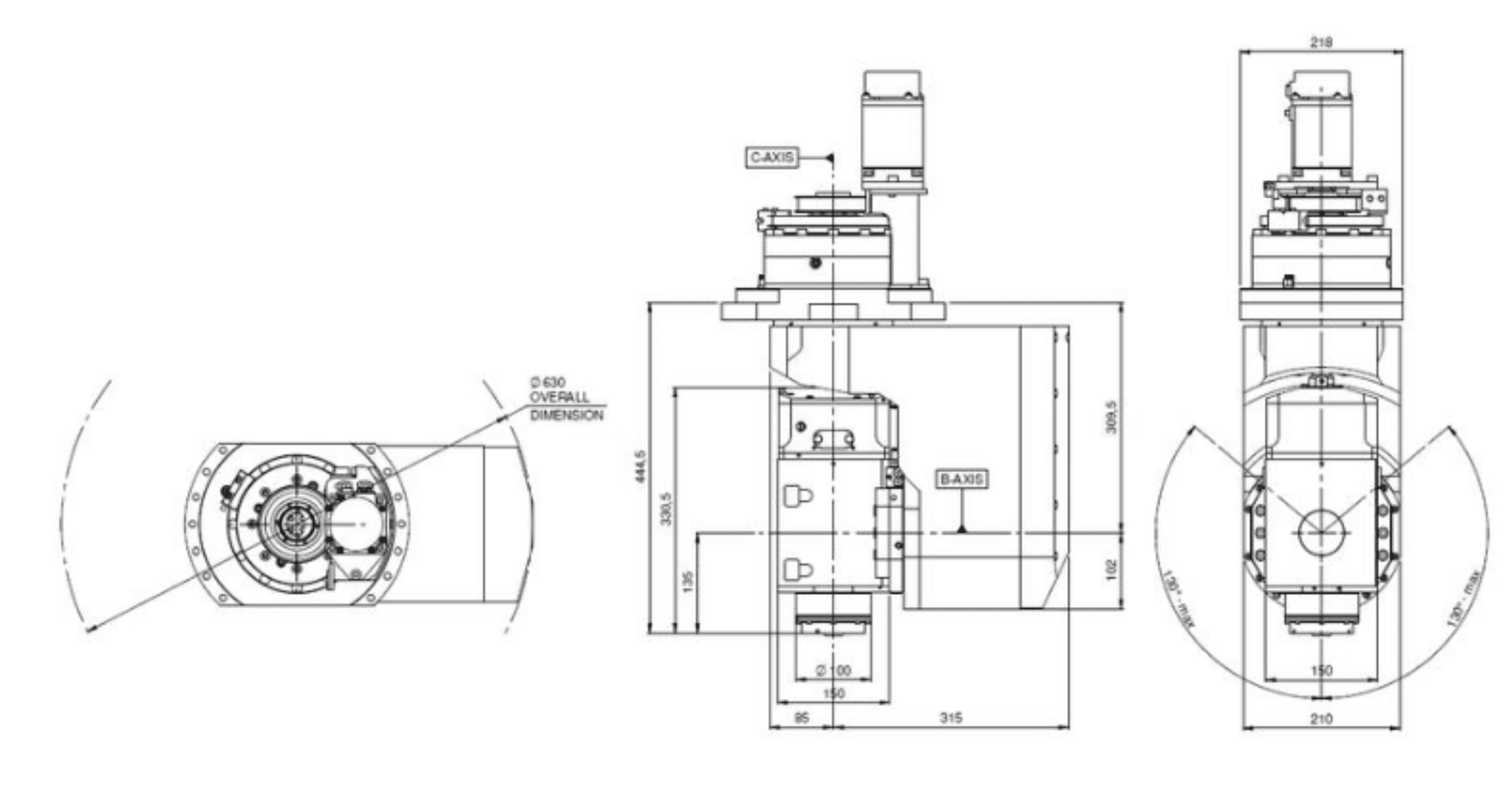

Tool holder type |

HSK F63 |

|

Tool cooling |

Micro pulses by means of CNC-controlled pump |

|

Spindle cooling system |

Liquid, with cooling unit |

|

Oil tank capacity |

2.2 Lt |

|

Number of nozzles |

2 |

|

X-axis travel Y-axis travel Z-axis travel A-axis rotation C-axis |

7.100 mm 680 mm 3 axes, 480 mm 4 axes 450 mm 180° 360° |

|

Max speed X Max speed Y Max speed Z Max speed A Max speed C |

100 m/min 60 m/min 30 m/min 3.600°/min 1.800°/min |

|

Tool storage spot |

15 (optional 15-32) |

|

Tool storage motor |

Brushless |

|

Reference stops |

2 |

|

Clamps Clamps displacement Clamp closing force |

8 standard (up to 16 on request), 4 per zone Automatic via trolley (motorized on request) 120 Kg |

|

Lubrication - trolley bearings Lubrication - screw carriage Lubrication - clamps |

Automatic - CNC managed Automatic - CNC managed Automatic - CNC managed |

|

Humidity limit |

75% |

|

Accuracy |

0.1 mm/m |

|

Monitor |

27" |

|

Operating system |

Win11 |

|

Connections |

USB (1 port), LAN, Wi-Fi |

|

MODEL |

9.0 |

|

Dimensions |

9.100 x 640 x 400 mm |

|

Transport dimensions |

L 13.000 W 2.400 H 2.700 mm |

|

Layout dimension standard |

L 11.800 W 3.400 H 3.200 mm |

|

Weight |

9.500 Kg |

|

Nominal power |

40 kw |

|

Consume power |

32 kW |

|

Required protection |

63 A differential thermal, 0.1 A, adjustable, 6.000 A magnetic) |

|

Voltage |

400 V, 3-phase + Neutral ±5% |

|

Frequency |

50/60 Hz |

|

Minimum air pressure |

7 bar |

|

Air consume |

230 NL/M |

|

Nominal power of Electrospindle |

18 kW s1 / 20 kW s6 |

|

Nominal torque |

14.3/15.9 Nm at 12.000 RPM |

|

Tool holder type |

HSK F63 |

|

Tool cooling |

Micro pulses by means of CNC-controlled pump |

|

Spindle cooling system |

Liquid, with cooling unit |

|

Oil tank capacity |

2.2 Lt |

|

Number of nozzles |

2 |

|

X-axis travel Y-axis travel Z-axis travel A-axis rotation C-axis |

9.100 mm 680 mm 3 axis, 480 mm 4 axis 450 mm 180° 360° |

|

Max speed X Max speed Y Max speed Z Max speed A Max speed C |

100 m/min 60 m/min 30 m/min 3.600°/min 1.800°/min |

|

Tool storage spot |

15 (optional 15-32) |

|

Tool storage motor |

Brushless |

|

Reference stops |

2 |

|

Clamps Clamp displacement Clamp closing force |

10 standard (up to 16 on request), 5 per zone Automatic via trolle (motorized on request) 120 kg |

|

Lubrication - trolley bearings Lubrication - screw carriage Lubrication - clamps |

Automatic - CNC managed Automatic - CNC managed Automatic - CNC managed |

|

Humidity limit |

75% |

|

Accuracy |

0.1 mm/m |

|

Monitor |

27" |

|

Operating system |

Win11 |

|

Connections |

USB (1 port), LAN, Wi-Fi |