❮

❯

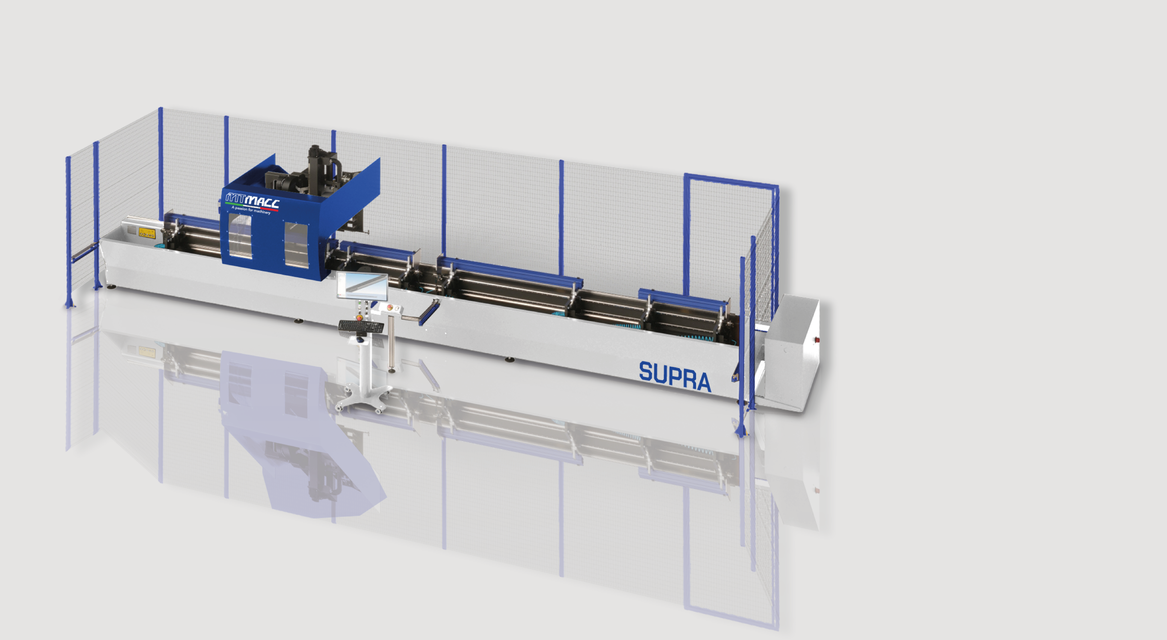

INDUSTRIAL MACHINERY DESIGNED FOR MULTIPLE WORKING PROCESSES

Perfect for the window, rail, automotive, aerospace and construction industries. The MC300 is a CNC work center designed to ensure maximum versatility and precision in the processing of steel, aluminum, light alloys and composite materials. Thanks to its modular structure, it is available in different configurations to adapt to the production needs of various industrial sectors.

Configurations and Adaptability

- Available in 7 and 4 meter versions, with the possibility of a compact 3 meter configuration, ideal for small spaces.

- Special versions with soundproof cabin and suction systems to ensure a safe and clean working environment

- Reinforced structure, designed for processing high density and resistance materials.

Innovation and Versatility

- 450 mm circular blade, with 3 kW motor, ideal for cutting and trimming profiles of all kinds.

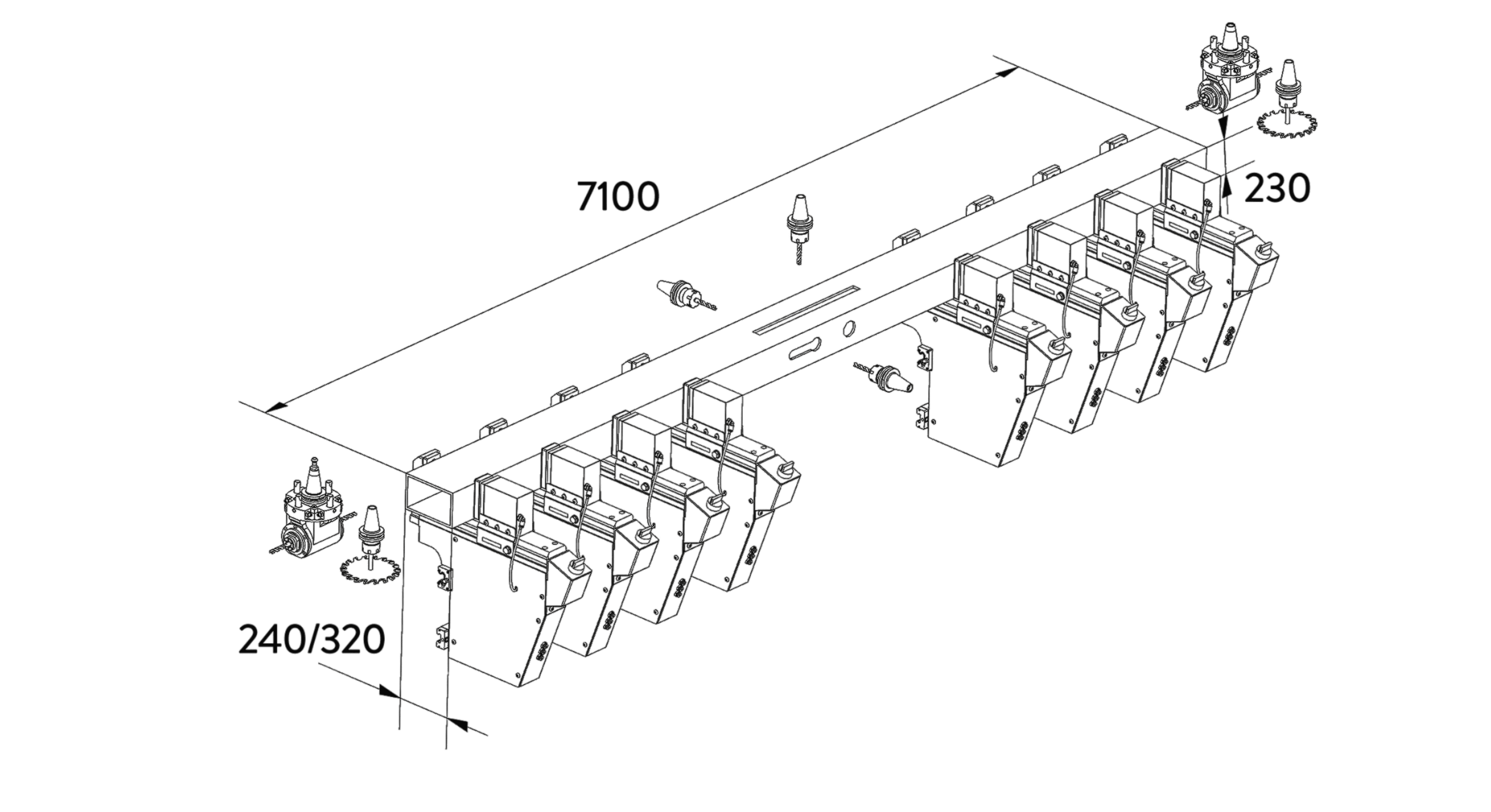

- 320 x 230 mm loading section, with 8 positions, compatible with disc cutters, tapping tools and angular transmissions.

- Advanced 3D CAD-CAM software, perfect for the window and door sector and other industrial applications.

Special Applications

The MC300 is designed to perform machining on complex materials, including fiberglass, steel and light alloys, adapting to the needs of advanced industrial sectors.

Strengths

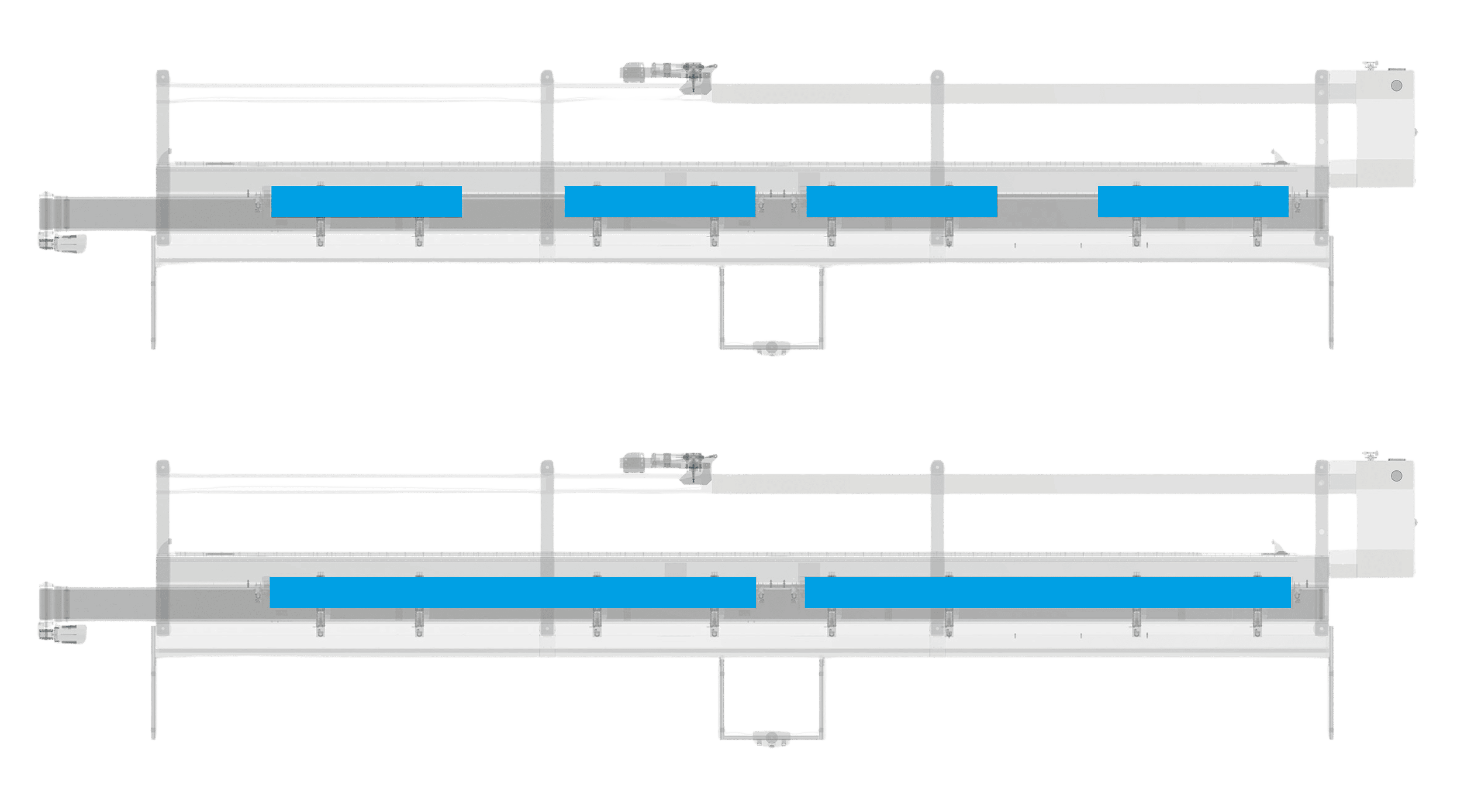

- Length from 3 to 11 meters, with single or double loading area for maximum efficiency.

- Maximum loading section 320 x 230 mm, ideal for advanced industrial processes.

- Enhanced 450 mm blade, can be equipped with a 3 kW spindle, for precision cuts.

- Perfect for processing aluminum and PVC profiles, ensuring maximum adaptability to production needs.

- Sound-absorbing cabin with suction system, for a safe and clean work environment.

|

MODEL |

4.0 |

|

Dimensions |

4.100 x 240 x 240 mm |

|

Transport dimensions |

L 5.900 W 2.400 H 2.200 mm // L.6.660 Cabin version |

|

Layout dimension standard |

L 6.400 W 3.200 H 2.600 mm // L 6.600 Cabin version |

|

Weight |

2.800 Kg // 3.600Kg Cabin version |

|

Nominal power |

16 kW |

|

Consume power |

12 kW |

|

Required protection |

25 A (termic: 32 A, differential 0.1 A, magnetic interruption 6.000 A) |

|

Voltage |

400 V, 3-phase + Neutral + Ground |

|

Frequency |

50/60 Hz |

|

Minimum air pressure |

0.65 Psi |

|

Air consume |

210 NL/M |

|

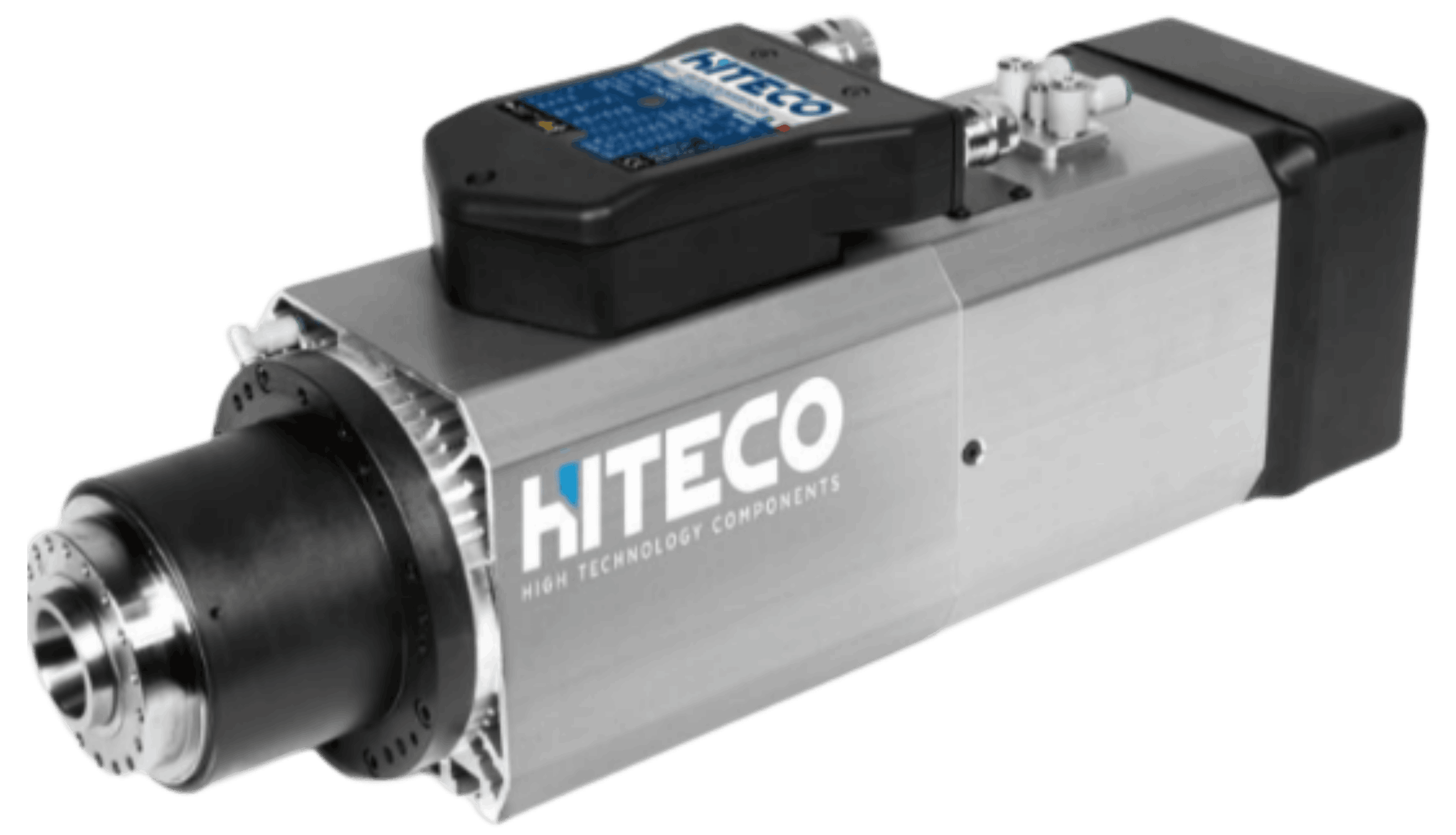

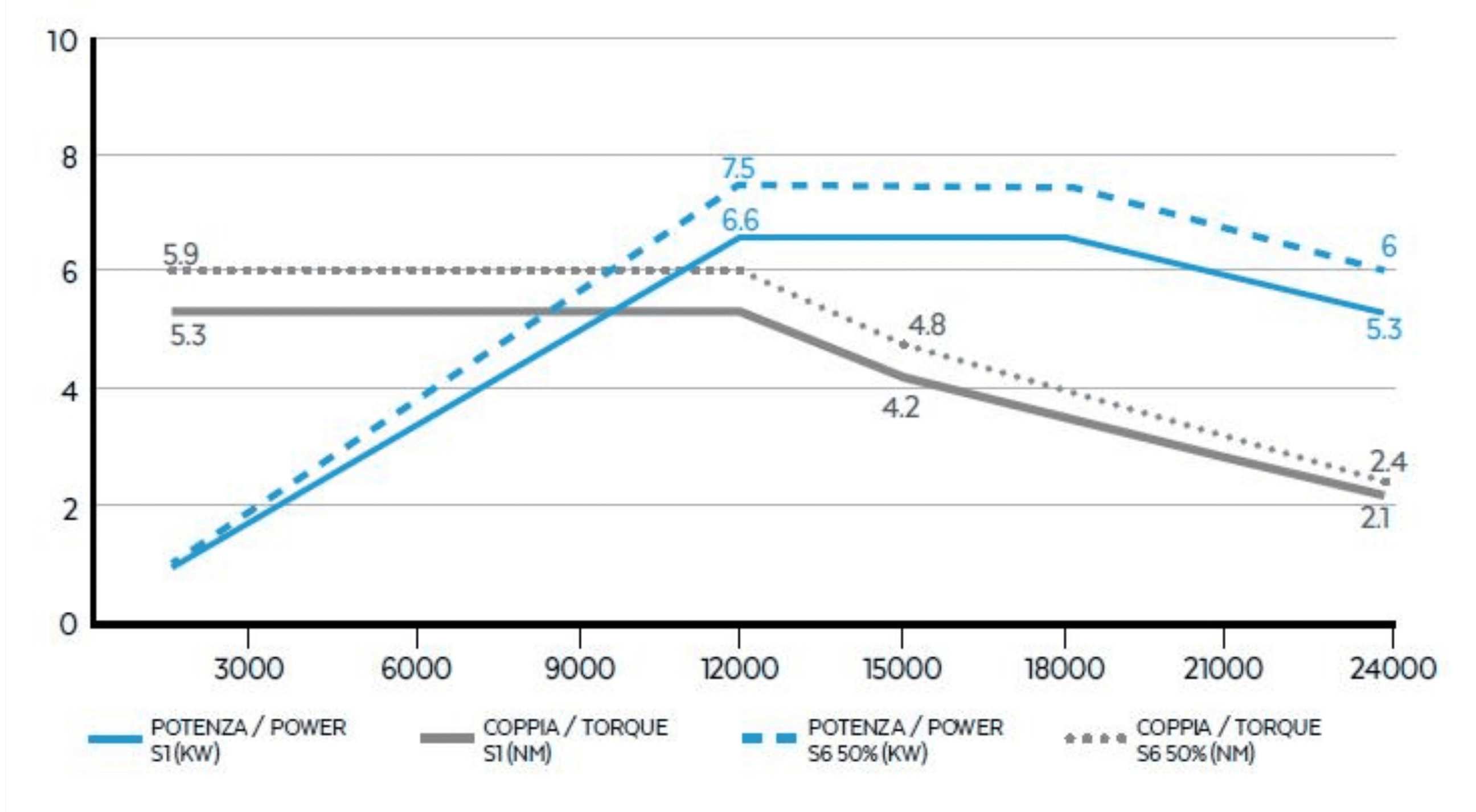

Nominal power of Electrospindle |

6.6 kW |

|

Nominal torque |

3.58 Nm at 12.000 RPM |

|

Tool holder type |

ISO30 |

|

Tool cooling |

Micro-drop lubrication with pure oil |

|

Spindle cooling system |

Electro fan |

|

Oil tank capacity |

1.5 Lt |

|

Number of nozzles |

1 |

|

X-axis travel Y-axis travel Z-axis travel A-axis rotation C-axis |

4.100 mm 240-320 mm 3 axis 240 mm 180° Not applicable to this model |

|

Max speed X Max speed Y Max speed Z Max speed A Max speed C |

80 m/min 60 m/min 30 m/min 3.600°/min Not applicable to this model |

|

Tool storage spot |

8 |

|

Reference stops |

1 (CNC managed, pneumatic movement) |

|

Clamps Clamp displacement Clamp closing force |

6 standard (up to 8 on request), 6 per zone Automatic via carriage (motorized on request) 80 kg |

|

Lubrication |

Manual (central greasing points for guides and screws) |

|

Humidity limit |

80% |

|

Accuracy |

0.1 mm/m |

|

Monitor |

27" |

|

Operating system |

Win11 |

|

Connections |

USB (1 port), LAN, Wi-Fi |

|

MODEL |

7.0 |

|

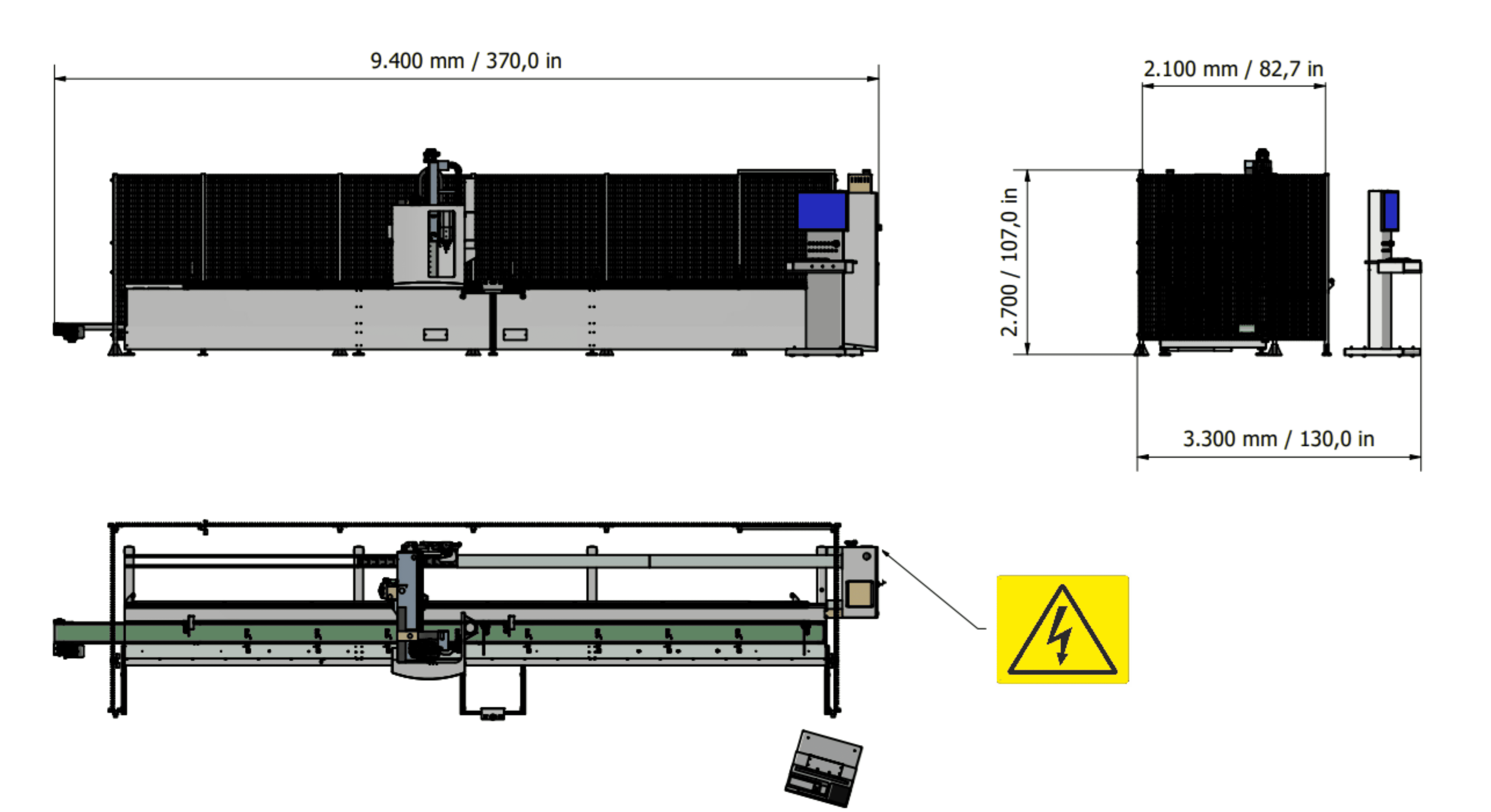

Dimensions |

7.100 x 320 x 240 mm |

|

Transport dimensions |

L 8.900 W 1.800 H 2.200 mm // L.6.660 Cabin version |

|

Layout dimension standard |

L 9.100 W 2.600 H 2.450 mm |

|

Weight |

2.800 Kg // 3.600Kg Cabin version |

|

Nominal power |

16 kW |

|

Consume power |

10 kW |

|

Required protection |

25 A (termic: 32 A, differential 0.1 A, magnetic interruption 6.000 A) |

|

Voltage |

400 V, 3-phase + Neutral + Ground |

|

Frequency |

50/60 Hz |

|

Minimum air pressure |

0.65 Psi |

|

Air consume |

240 NL/M |

|

Nominal power of Electrospindle |

6.6 kW |

|

Nominal torque |

3.58 Nm at 12.000 RPM |

|

Tool holder type |

ISO30 |

|

Tool cooling |

Micro-drop lubrication with pure oil |

|

Spindle cooling system |

Electro fan |

|

Oil tank capacity |

1.5 Lt |

|

Number of nozzles |

1 |

|

X-axis travel Y-axis travel Z-axis travel A-axis rotation C-axis |

7.100 mm 230-320 mm 3 axis 230 mm 180° Not applicable to this model |

|

Max speed X Max speed Y Max speed Z Max speed A Max speed C |

80 m/min 60 m/min 30 m/min 3.600°/min Not applicable to this model |

|

Tool storage spot |

8 |

|

Reference stops |

1 (CNC managed, pneumatic movement) |

|

Clamps Clamp displacement Clamp closing force |

8 standard (up to 12 on request), 4 per zone Automatic via carriage (motorized on request) 80 kg |

|

Lubrication |

Manual (central greasing points for guides and screws) |

|

Humidity limit |

80% |

|

Accuracy |

0.1 mm/m |

|

Monitor |

27" |

|

Operating system |

Win11 |

|

Connections |

USB (1 port), LAN, Wi-Fi |